Lawrence Livermore discovery could improve biofuel production

Lawrence Livermore National Laboratory

April 4, 2014

BY Lawrence Livermore National Laboratory

Resistance is not futile when it comes to a new method to more efficiently convert biomass to biofuels.

New research by scientists from Lawrence Livermore National Laboratory in conjunction with the Joint BioEnergy Institute suggests that a type of bacterial resistance may provide more efficient production of biofuels.

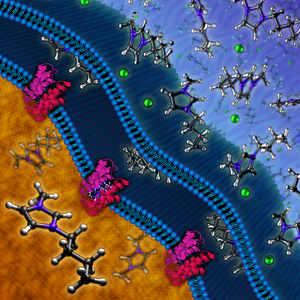

The team identified the genetic origin of bacterial resistance to an ionic liquid (a salt in the liquid state), which they successfully introduced into a strain of E. coli bacteria for the production of advanced biofuels. The ionic liquid resistance is based on a pair of genes discovered in a microbial species native to a tropical rainforest in Puerto Rico.

"Ionic liquids are used as potent solvents to extract cellulose from biomass, so that it can be broken down to sugars used by microbes to make advanced biofuels -- new liquid fuels that go beyond ethanol and can replace gasoline or diesel," said Michael Thelen, an LLNL biochemist who also is part of JBEI's Deconstruction Division.

The team identified two genes in Enterobacter lignolyticus, a rainforest soil bacterium that is tolerant to specific ionic liquids, and transferred them as part of a genetic module into an E. coli biofuel host. The genetic module conferred the tolerance needed for the E. coli to grow well in the presence of toxic concentrations of ionic liquids. As a result, production of a terpene-based biofuel was enhanced.

The research appears in the March 26 edition of the journal, Nature Communications.

At JBEI, researchers have previously engineered strains of E. coli bacteria to digest the cellulosic biomass of switchgrass, a perennial grass that thrives on land not suitable for food crops, and convert its sugars into biofuels and chemicals. However, the ionic liquids used to make the switchgrass digestible proved to be too toxic for the E. coli and had to be completely removed through several washings prior to fermentation.

"The new genes confer to E. coli the ability to grow in the presence of normally toxic levels of an ionic liquid, making it possible to produce biofuels more efficiently," Thelen said. "The consequences of this study pave the way for further improvements in the microbial conversion of biomass to biofuels."

In this latest study, JBEI researchers used an approach devised by lead author and Basel University graduate student and LLNL guest researcher Thomas Ruegg to rapidly pinpoint the genes responsible for ionic liquid resistance in the genomic DNA of Enterobacter lignolyticus. "This genetic module encodes both a membrane transporter and its transcriptional regulator," Ruegg said. "While a pump exports ionic liquids, the substrate-inducible regulator maintains the appropriate level of this pump so that the microbe can grow normally either in the presence or absence of ionic liquid."

The results are likely to eliminate a bottleneck in JBEI's biofuels production strategy, which relies on ionic liquid pretreatment of cellulosic biomass. The research also demonstrates how the adverse effects of ionic liquids can be turned into an advantage, by inhibiting the growth of other bacteria. This research was funded by the DOE Office of Science.

Advertisement

Advertisement

Related Stories

The U.S. Department of Energy Bioenergy Technologies Office (BETO) announced up to $23 million in funding to support research and development (R&D) of domestic chemicals and fuels from biomass and waste resources.

The U.S. DOE has announced its intent to issue funding to support high-impact research and development (R&D) projects in two priority areas: sustainable propane and renewable chemicals and algal system cultivation and preprocessing.

Sens. Sherrod Brown, D-Ohio, and Pete Ricketts, R-Neb., in August introduced the Renewable Chemicals Act, a bill that aims to create a tax credit to support the production of biobased chemicals.

The Chemical Catalysis for Bioenergy Consortium, a consortium of the U.S. DOE’s Bioenergy Technologies Office, has launched an effort that aims to gather community input on the development of new biomass processing facilities.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

Upcoming Events