Lygos completes pilot-scale production of malonic acid

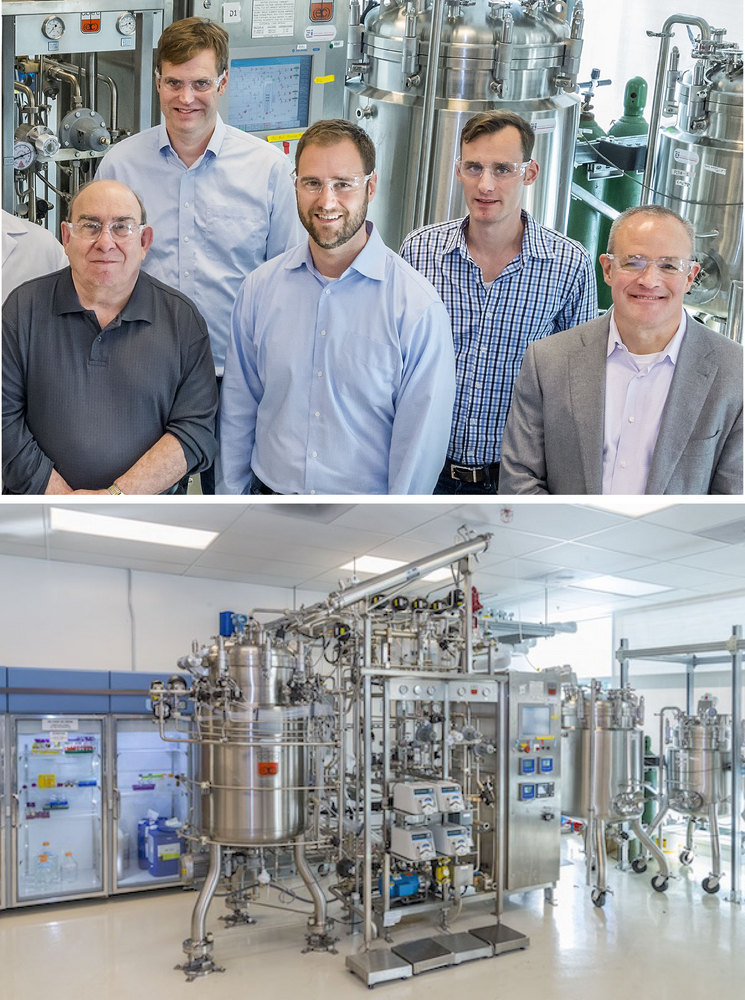

Roy Kaltschmidt, Lawrence Berkeley National Laboratory

March 10, 2015

BY Katie Fletcher

Lygos Inc., an industrial biotechnology company, recently announced that it has successfully achieved pilot-scale production of malonic acid from sugar. Malonic acid is a high-value specialty chemical useful for production of a variety of pharmaceuticals, flavors, fragrances, electronic and metal manufacturing processes. Lygos has identified over $1 billion in derivative specialty and commodity chemicals that can be accessed from malonic acid. “Malonic acid is a building block to a number of other products, so I anticipate value being created in a number of areas,” said Eric Steen, CEO of Lygos.

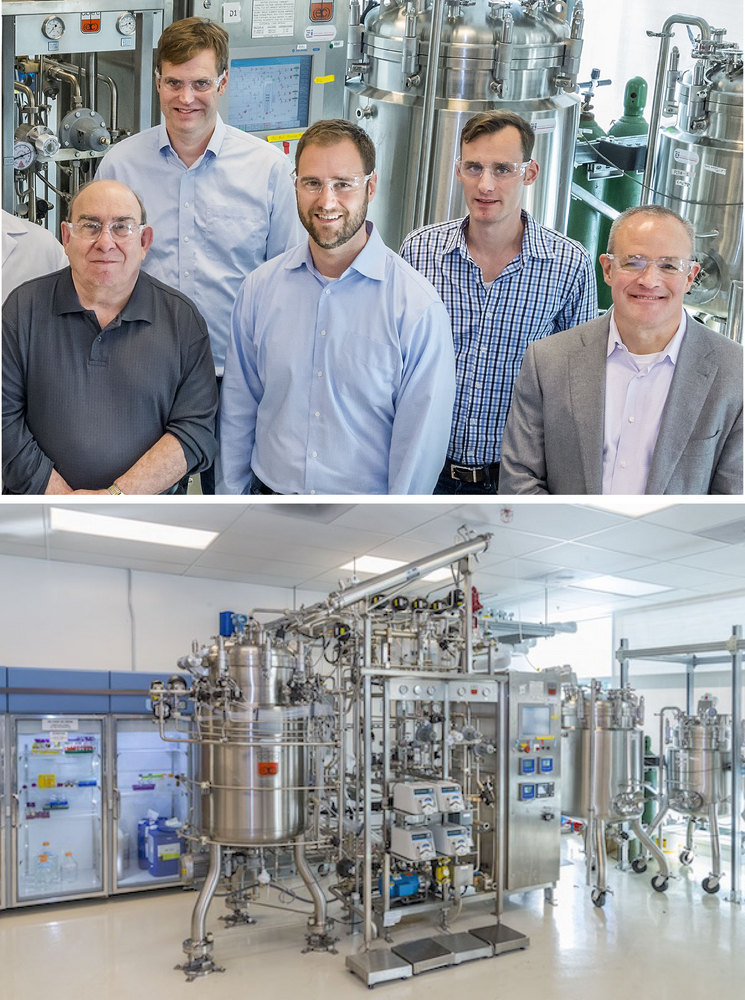

Lygos began developing its malonic acid fermentation technology in 2011. At that time there was no known fermentation process or micro-organism to produce malonic acid, although it had been sought after as an industrial biotech product, according to Steen. Lygos is now over three years into its malonic acid program, and during that time transitioned the process from lab scale into a larger fermentation facility that could support on the order of 1 to 10 tons of product annually.

The scale up was performed at the Advanced Biofuels Process Demonstration Unit at Lawrence Berkeley National Laboratory. “The process metrics we observed at lab scale were successfully transitioned to pilot scale,” Steen said. “With this manufacturing run, we are able to provide samples of high quality malonic acid to customers and partners.”

Biomass Magazine reported last October that Lygos, which evolved from the U.S. DOE’s Joint BioEnergy Institute, received two grants under the USDA’s National Institute of Food and Agriculture Small Business Innovation Research program. One of the grants went towards this malonic acid development.

Advertisement

Advertisement

Now that successful pilot-scale production is achieved, the company has early commercialization efforts underway. Although, Steen said they have additional process improvements that can be garnered and will further advance the technology before full commercialization. “The pilot-scale production confirmed the scalability of Lygos’ process,” Steen said. “As we move forward with commercialization, we're seeking partners across the bioproducts value chain, starting with feedstock providers and spanning contract or existing fermentation facilities, and downstream product developers."

The current petrochemical manufacturing process to produce this acid requires chloracetic acid and sodium cyanide, which are both expensive and environmentally hazardous. Lygos has developed a fermentation technology that hopes to solve these problems. The technology decreases CO2 emissions, eliminates toxic inputs and the company believes could replace the existing petroleum production process for malonic acid at a lower cost using less energy.

“We’ve been excited about malonic acid because it has some unique chemistry that could enable new materials, products and manufacturing processes, while displacing the existing toxic, drop-in petroleum product,” Steen said. “As Lygos' first compound, it is one of the highest yielding compounds that can be produced in a fermentation process using renewable biomass sugars—our production costs are estimated to be less than incumbent producers' raw material cost. It's truly a ‘bio-advantaged’ product.”

The U.S. DOE labeled the compound as one of the top 30 value-added chemicals to be produced from biomass-derived sugar, instead of petroleum. “We’ve been working with some of the most promising technologies in order to ensure our process and microbe can integrate with upstream cellulosic sugar,” Steen said. “The sugars can be extracted from a variety of sources like agricultural residues (eg. corn stover, sugar cane bagasse or dedicated bioenergy crops like miscanthus), or forest residues (eg. wood chips, etc.).”

Advertisement

Advertisement

Related Stories

The U.S. Department of Energy Bioenergy Technologies Office (BETO) announced up to $23 million in funding to support research and development (R&D) of domestic chemicals and fuels from biomass and waste resources.

The U.S. DOE has announced its intent to issue funding to support high-impact research and development (R&D) projects in two priority areas: sustainable propane and renewable chemicals and algal system cultivation and preprocessing.

Sens. Sherrod Brown, D-Ohio, and Pete Ricketts, R-Neb., in August introduced the Renewable Chemicals Act, a bill that aims to create a tax credit to support the production of biobased chemicals.

The Chemical Catalysis for Bioenergy Consortium, a consortium of the U.S. DOE’s Bioenergy Technologies Office, has launched an effort that aims to gather community input on the development of new biomass processing facilities.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

Upcoming Events