Metabolic path to improved biofuel production

Lawrence Berkeley National Laboratory

March 4, 2015

BY Lawrence Berkeley National Laboratory

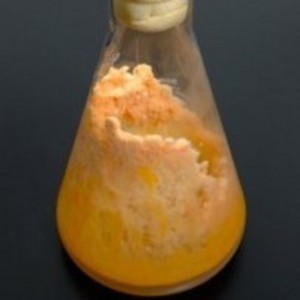

Researchers with the Energy Biosciences Institute, a partnership that includes Lawrence Berkeley National Laboratory and the University of California, Berkeley, have found a way to increase the production of fuels and other chemicals from biomass fermented by yeast. By introducing new metabolic pathways into the yeast, they enable the microbes to efficiently ferment cellulose and hemicellulose, the two major families of sugar found in the plant cell wall, without the need of environmentally harsh pre-treatments or expensive enzyme cocktails.

“We’ve discovered new chemicals generated by fungi and bacteria as metabolites in their strategy for consuming the plant cell wall that are a general part of the global carbon cycle,” says Jamie Cate, a staff scientist in Berkeley Lab’s Physical Biosciences Division and a professor of biochemistry, biophysics and structural biology at UC Berkeley. “We should now be able engineer biofuel-producing yeast to do what these fungi and bacteria do, opening up many new possible scenarios for making biofuels and other important products.”

The cost of gasoline at the pump may be going down, but the excessive carbon being released into the atmosphere continues to escalate. Clean, green and renewable transportation fuels are needed to replace gasoline, diesel and jet fuel. Also needed are green and sustainable alternatives to petro-chemicals. Microbial fermentation of the cellulosic sugars stored in plant cell walls and other forms of biomass is a highly promising source of biofuels and chemicals provided the process can be done with sufficient economy. This requires the conversion of complex sugars into simple sugars that can be fermented.

Advertisement

Advertisement

Working through the EBI, Cate and a team of collaborators identified metabolic pathways in the fungus Neurospora crassa that are used to digest xylose, one of the most abundant sugars in hemicellulose. Yeast, Saccharomyces cerevisiae, the microbe most commonly used for the production of biofuels, can’t ferment xylose.

“In contrast to S. cerevisiae, many cellulolytic fungi including N. crassa naturally grow well on both the cellulose and hemicellulose components of the plant cell wall,” Cate says. “By using functional genomics data and N. crassa knockout strains, we identified separate pathways used by N. crassa to consume the cellodextrins and xylodextrins released from plant cell walls by its secreted enzymes.”

To enable the N. crassa metabolic pathways to work in yeast, Cate and his collaborators introduced five new genes into the yeast. While the new pathways and genes allow the yeast to directly ferment xylose sugars into a desired biofuel or chemical product, those sugars still have to be released from the plant cell walls. This can be done, however, with a simple hot water-pretreatment rather than the acids or ionic liquids that current pre-treatment methods deploy. Harsh chemicals like acids and ionic liquids, unlike hot water, must be removed prior to fermentation so as not to harm the microbes. This is another major expense in addition to the expensive enzymes required to break down the xylose sugars.

Advertisement

Advertisement

“We believe that introducing N. crassa metabolic pathways into yeast could find widespread use in helping to overcome existing bottlenecks to the fermentation of lignocellulosic feedstocks as a sustainable and economical source of biofuels and renewable chemicals,” Cate says.

The results of this research have been published in eLife. The paper is titled “Expanding xylose metabolism in yeast for plant cell wall conversion to biofuels.” Cate is the corresponding author. Co-authors are Xin Li, Vivian Yu, Yuping Lin, Kulika Chomvong, Raíssa Estrela, Annsea Park, Julie Liang, Elizabeth Znameroski, Joanna Feehan, Soo Rin Kim, Yong-Su Jin and Louise Glass.

This research was funded by EBI.

Related Stories

The U.S. Department of Energy Bioenergy Technologies Office (BETO) announced up to $23 million in funding to support research and development (R&D) of domestic chemicals and fuels from biomass and waste resources.

The U.S. DOE has announced its intent to issue funding to support high-impact research and development (R&D) projects in two priority areas: sustainable propane and renewable chemicals and algal system cultivation and preprocessing.

Sens. Sherrod Brown, D-Ohio, and Pete Ricketts, R-Neb., in August introduced the Renewable Chemicals Act, a bill that aims to create a tax credit to support the production of biobased chemicals.

The Chemical Catalysis for Bioenergy Consortium, a consortium of the U.S. DOE’s Bioenergy Technologies Office, has launched an effort that aims to gather community input on the development of new biomass processing facilities.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

Upcoming Events