Metathesis processing improves biodiesel oil dilution issues

October 28, 2013

BY Ron Kotrba

For several years now, concerns have existed with using higher-level biodiesel blends in new diesel vehicles that employ late post-injection for particulate filter regeneration, mainly because of engine oil dilution issues resulting from biodiesel’s higher boiling point. Unlike the petroleum portion of a blended fuel that seeps into the crankcase and then evaporates back out, biodiesel’s higher boiling temperature allows it to accumulate in the engine oil and stay there, causing concerns of premature engine wear if oil change intervals are not adjusted.

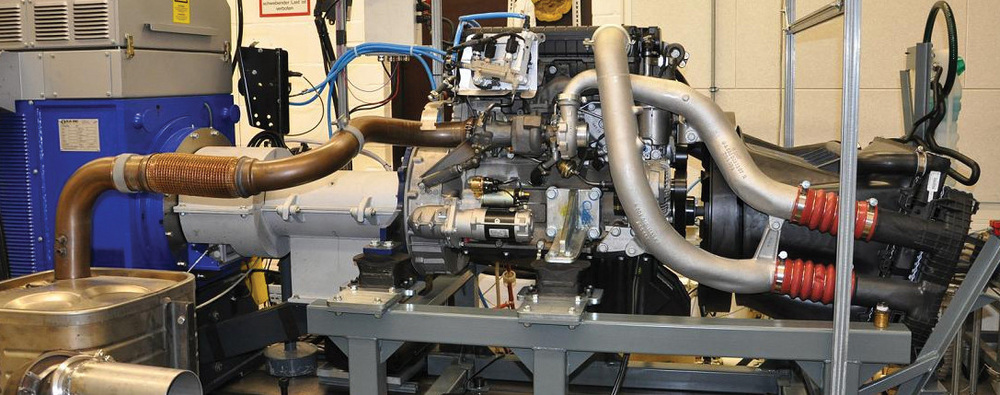

A project carried out at the Johann Heinrich von Thünen-Institut in cooperation with the Karlsruhe Institute of Technology, the Institute for Internal Combustion Engines of the Technical University of Braunschweig, the Steinbeis-Transfer Center for Biofuels and Environmental Measuring, Coburg, and the Technology Center Automotive of the University of Applied Sciences in Coburg, aimed to adjust the boiling behavior of biodiesel to that of petro diesel fuel.

The change of biodiesel molecules through metathesis, as a design tool, was extremely effective for the adaptation of the boiling behavior of a fuel. Metathesis is a special chemical reaction known from the oleochemistry industry, but it hasn’t really been applied to tailoring biofuels.

Starting from rapeseed oil methyl ester, composed largely of oleic, linoleic and linolenic acid, the catalyst-assisted metathesis reaction with 1-hexene as further reagent led to a variation of the chain lengths, which significantly influenced the boiling line of the produced fuel.

Advertisement

Investigations were done of the fuel’s properties, such as mixing with other fuels and engine oil, as well as the material compatibility with selected polymers.

Subsequent engine tests comprised both analyses of the burning behavior of the fuels as well as determination of the exhaust gas emissions. In addition to the regulated emissions, ammonia, polycyclic aromatic hydrocarbons, carbonyls, mutagenicity and particle size distribution were also examined.

The investigation results indicate that metathesis fuels appear well-suited for use in modern diesel engines that use late-post injection.

Advertisement

Related Stories

ATOBA Energy and Air Moana are partnering to implement scalable solutions for the supply of SAF. The collaboration aims to ensure long-term SAF availability while supporting local initiatives to develop sustainable fuel production in Tahiti.

Kintetsu World Express Inc. has signed an additional agreement with Hong Kong, China-based Cathay Pacific Airways for the use of sustainable aviation fuel (SAF). The agreement expands a three-year partnership between the two companies.

Broco Energy on July 17 announced a new partnership with the Massachusetts Port Authority (Massport) to deliver and transition Massport's fuel tanks to renewable diesel across its various facilities.

Shell Aviation, Accenture, and Amex GBT on July 10 announced Avelia is in the process of evolving to an industry solution with independent data hosting and a multi-supplier model helping users access the GHG benefits of SAF.

Avia Solutions Group, the world's largest ACMI (aircraft, crew, maintenance, and insurance) provider, has partnered with DHL Express to reduce greenhouse gas emissions from its international shipments using SAF.

Upcoming Events