New NIR models speedup feedstock analysis process

PHOTO: CELIGNIS

September 15, 2015

BY Daniel Hayes

Efficient cellulosic ethanol processes will depend upon the accurate analysis of lignocellulosic feedstocks. The relative importance of various biomass constituent properties depends largely on whether enzymatic hydrolysis or thermochemical technologies are used, with sugar compositions being paramount in hydrolysis and thermal properties more important in thermochemical processes.

The analytical techniques for biomass used in thermochemical processes are well-established, relatively rapid and low-cost, largely due to their use in the fossil fuel industry. Moisture and ash contents are determined using ovens and furnaces, respectively. Heating values are determined using an oxygen bomb calorimeter and applying corrections based on the elemental (carbon, oxygen, hydrogen, nitrogen, sulphur) composition of the sample, found using an elemental analyzer. The washings of the calorimeter can also be used to find the chlorine content. Other important elements in the ash can be determined by digesting the sample and subsequent analysis using equipment such as an ICP (inductively coupled plasma). The ash melting behavior can be determined using a special furnace with a digital camera to monitor ash deformation. These methods place the onus of analysis on dedicated equipment, rather than the analyst, and can be completed within one day.

It takes significantly longer to determine the properties relevant to hydrolysis processes, however, and these methods are much more reliant on careful work by the analyst. The National Renewable Energy Laboratory has developed a widely used series of laboratory analytical procedures (LAPs) for lignocellulosic analysis. The LAP used to determine constituent sugars and lignin takes approximately three days for the two-stage acid hydrolysis procedure. Before hydrolysis, however, it is usually necessary to remove extractives from the sample. In trials in our laboratory, we have found that not removing the extractives prior to hydrolysis can lead to significant overestimations of the Klason lignin. While various solvents can be used to remove extractives, the NREL LAP recommends water and ethanol. Removing extractives using soxhlet requires up to 24 hours per sample. The remaining solid needs to air-dry prior to hydrolysis and the extractives content can be determined indirectly from the solid mass loss or directly by evaporating the solvent and weighing.

Once the extractives are removed, the two-stage acid hydrolysis procedure specified in the NREL LAP involves mixing the sample with 72 percent sulphuric acid and incubating it in a water batch at 30 degrees Celsius for one hour, during which the sample needs to be periodically mixed. The analyst’s mixing technique is key in ensuring that the sample is fully hydrolyzed. After one hour, the hydrolysate is diluted to 4 percent acid, the pressure tube sealed and placed in an autoclave at 121 C for another hour. The hydrolysate is then filtered and analyzed using chromatography equipment to identify the sugars. The residue is dried and ashed to determine the Klason lignin content, while acid-soluble lignin content is determined using ultraviolet spectroscopy.

Given that it takes approximately two weeks to follow the NREL LAPs, the cost of analysis can be very high.

Rapid Biomass Analysis

Fortunately, there are rapid analysis methods available for lignocellulosic composition. Near-infrared spectroscopy (NIR) involves light just beyond the visible part of the electromagnetic spectrum being directed toward the sample where it is reflected from, transmitted or refracted through, or absorbed by the matter it interacts with. Whether absorption occurs will depend on whether the photons have a frequency resonant to that of the rotations or the characteristic vibrations of the chemical bonds that constitute the molecules of the sample. Typically, most of the fundamental vibrational absorptions occur in the mid-infrared region (MIR), called the fingerprint region because distinctive spectra can be obtained for specific molecules and compounds. In contrast, the NIR region consists of the much weaker absorbance-intensity overtones and combination bands. The number and complexity of these, and their interactions, result in spectra that cannot easily be evaluated on visual inspection.

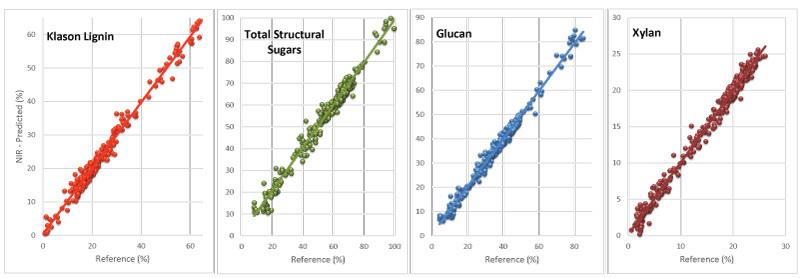

Because of this, NIR is not a direct analytical method. Statistical models based on Chemometric methods can be developed to relate the spectra variations with the chemical variations seen in the samples. Once robust models are developed, they can be applied for rapid and direct analysis of unknown samples, becoming primary NIR analytical tools.

NIR models work best when the samples used in their development are comparable to the targeted unknowns—a model developed on grass samples is unlikely to be accurate in predicting the composition of a wood sample. Given the huge variability in both biomass types and compositions seen in advanced biofuel feedstocks, NIR models need to be developed from a large and broad calibration set in order to predict analytes with confidence.

While NIR is a well-established method in the food and forage industries, with manufacturers selling NIR devices with built-in models for predicting a range of properties, such as protein in grain, its application for analyzing biomass feedstocks for lignocellulosic properties has been limited until recently. While there have been a number of research publications in this area, these typically only involved one feedstock, or at most a handful. There have also been some in-house NIR models, usually also feedstock-specific, developed by companies in the advanced biofuels sector. Historically, the only means of lignocellulosic analysis for a user without access to these models would have been through the chemical analysis methods, either carried out themselves or by a companies that undertake the NREL LAPs as a commercial service (with prices being approximately $1,000 per sample for full sugars, lignin and extractives analysis).

To meet the emerging need, Celignis Ltd. was launched in August at the Nexus Innovation Center at the University of Limerick, Ireland, to provide 24-hour, relatively low-cost laboratory analytical services for the characterization of biomass samples, including NIR analysis. Over 1,300 samples, covering a wide variety of biomass types, have been used to develop the Celignis models. They can predict each of the polysaccharide sugars (glucose, xylose, mannose, arabinose, galactose and rhamnose), lignin (Klason and acid soluble), ash and ethanol-soluble-extractives, covering a broad concentration range for each of the constituents.

Of course, the most accurate means of analysis will always be the chemical method, providing the analyst is suitably trained. However, we consider the accuracy of NIR predictions more than satisfactory for the evaluation of advanced biofuel feedstocks. In the future, biomass NIR devices may be integrated online at biofuel production facilities. We have demonstrated in our laboratory that models using wet, whole biomass samples can be highly accurate on a feedstock-specific basis, though slightly less accurate than models based on dried, ground samples. Such a rapid means of online analysis will allow for efficiency improvements in feedstock evaluation and payment to the supplier, and even more rapid process adjustments.

Author: Daniel Hayes,

CEO, Celignis Ltd.

(+353) 61 518 440

dan@celignis.com

Advertisement

Advertisement

Related Stories

Scientists at ORNL have developed a first-ever method of detecting ribonucleic acid, or RNA, inside plant cells using a technique that results in a visible fluorescent signal. The technology could help develop hardier bioenergy and food crops.

The 2025 International Fuel Ethanol Workshop & Expo, held in Omaha, Nebraska, concluded with record-breaking participation and industry engagement, reinforcing its role as the largest and most influential gathering in the global ethanol sector.

TotalEnergies and Quatra, the European market leader in the collection and recycling of used cooking oil, have signed a 15-year agreement beginning in 2026, for the supply of 60,000 tons a year of European used cooking oil.

The USDA maintained its forecast for 2025-’26 soybean oil use in biofuel production in its latest World Agricultural Supply and Demand Estimates report, released June 12. The estimate for 2024-’25 soybean use in biofuel production was revised down.

SkyNRG on June 5 released its fifth Sustainable Aviation Fuel Market Outlook. The report, developed in collaboration with ICF, highlights the need to scale up technologies and feedstocks that are an alternative to HEFA fuels.

Upcoming Events