NJ company unveils low-cost CO2-to-chemical process

March 5, 2014

BY Sue Retka Schill

A new process to convert carbon dioxide to chemicals has been unveiled by New Jersey-based Liquid Light Corp. The core technology uses low-energy catalytic electrochemistry to convert CO2 to chemicals, combined with hydrogenation and purification operations. The company says its technology can be used to produce more than 60 chemicals, but its initial focus has been on ethylene glycol (MEG). With a $27 billion market, MEG is used for a wide range of consumer products including plastic bottles, antifreeze and polyester clothing.

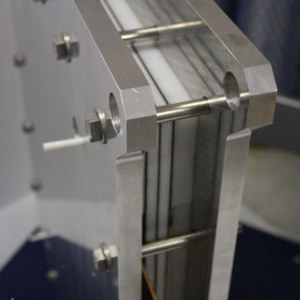

Liquid Light announced its demonstration-scale reactor cell has validated laboratory tests showing the process meets targets for energy per unit of output, rate of production, yield, and stability and longevity of reactor cell components. Where other processes to manufacture MEG require $617 to $1,113 of feedstocks derived from natural gas, oil or corn, Liquid Light says its process requires $125 or less of CO2 to make a ton that will sell for $700 to $1,400 per ton.

The process will reduce the carbon footprint for chemical production compared to conventional methods, the company said, while pointing to other greenhouse gas reduction potential. In addition to sequestering carbon when using renewable energy sources, it can be powered by intermittently-available renewable energy sources like solar and wind.

Advertisement

Advertisement

“We’re delighted to be introducing a new and valuable alternative for the mainstream chemical industry,” said Kyle Teamey, CEO of Liquid Light. “Liquid Light’s technology offers a new and cost-effective way to make everyday products from plain old carbon dioxide. This is a great way to reduce our dependence on fossil fuels while we simultaneously consume an environmental pollutant.”

The New Jersey-based startup company was co-founded by Princeton University chemistry professor, Andrew Bocarsly, and a former graduate student, Emily Cole. Cole serves as director of chemistry at the company and Bocarsly leads the team of scientific advisors. First developed in the early 1990s, Liquid Light intends to license its technology, backed by more than 100 patents and applications. Investors include VantagePoint Capital Partners, BP Ventures, Chrysalix Energy Venture Capital, and Osage University Partners.

Advertisement

Advertisement

Related Stories

The U.S. Department of Energy Bioenergy Technologies Office (BETO) announced up to $23 million in funding to support research and development (R&D) of domestic chemicals and fuels from biomass and waste resources.

The U.S. DOE has announced its intent to issue funding to support high-impact research and development (R&D) projects in two priority areas: sustainable propane and renewable chemicals and algal system cultivation and preprocessing.

Sens. Sherrod Brown, D-Ohio, and Pete Ricketts, R-Neb., in August introduced the Renewable Chemicals Act, a bill that aims to create a tax credit to support the production of biobased chemicals.

The Chemical Catalysis for Bioenergy Consortium, a consortium of the U.S. DOE’s Bioenergy Technologies Office, has launched an effort that aims to gather community input on the development of new biomass processing facilities.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

Upcoming Events