Novozymes: Advanced enzymes increase ethanol yield, plant profit

Novozymes

August 22, 2017

BY Novozymes

Novozymes has announces the launch of Spirizyme 2.0 T and Spirizyme Ultra T for the European ethanol market. The two products are part of the Spirizyme T Portfolio, an advanced suite of glucoamylase enzymes with trehalase that deliver yield enhancing activities documented to provide the highest total sugar conversion in the industry.

“Reducing residual sugar, such as trehalose, through better conversion, generates up to EUR 850,000 more ethanol revenue for the plant,” says Thomas Schrøder, vice president, biorefining commercial. “Extensive plant trials of the Spirizyme T products have shown that they reduce the amount of residual DP2 sugars by up to 70 percent.”

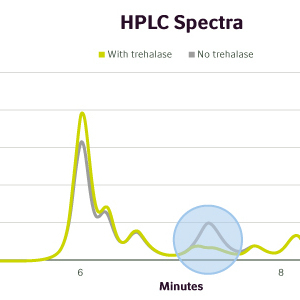

Trehalose, a type of sugar that is normally left unfermented in a standard ethanol plant, is targeted by the trehalase enzyme to produce glucose, which is then fermented to ethanol.

Trehalose makes up a significant part of the ‘DP2 peak’, which is a measure of disaccharides and contributes to the overall residual sugar in an ethanol plant. The more DP2 an ethanol plant can convert, the more ethanol it will produce.

Advertisement

Advertisement

Proven technology coupled with advanced technical services

The Spirizyme T product portfolio is based on proven technology with low risk of process errors. The solution can be easily integrated in the production. The portfolio is built on industry known glucoamylase blends, now with the addition of trehalase to further enhance performance.

From managing and analyzing plant data, Novozymes’ technical field scientists are equipped to understand the critical process conditions that determine which enzyme product is best suited for each individual plant. These technical teams are also a key resource in helping customers optimize product dosing for the best results.

Advertisement

Advertisement

“Apart from industry-leading conversion technology, we have a proven ability of delivering strong technical services, and of working with data-driven performance improvement,” adds Thomas Schrøder. “When our field scientists help optimize processes at the plants, alongside customers, magic happens in terms of more yields and more profits.”

Customers can get further support from Novozymes’ Bioenergy University, which provides customized education and training to help plant employees advance their skills and knowledge.

Related Stories

Calumet Inc. on Aug. 8 confirmed its Montana Renewables biorefinery is currently running at full capacity. An initial phase of the company’s MaxSAF initiative remains on track to boost SAF capacity to up to 150 MMgy by mid-2026.

Marathon Petroleum Corp. on Aug. 5 released second quarter financial results, reporting improved EBITDA for its renewable diesel segment. The company primarily attributed the improvement to increased utilization and higher margins.

Chevron Corp. on Aug. 1 confirmed the company started production at the Geismar renewable diesel plant in Louisiana during the second quarter after completing work to expand plant capacity from 7,000 to 22,000 barrels per day.

The public comment period on the U.S. EPA’s proposed rule to set 2026 and 2027 RFS RVOs and revise RFS regulations closed Aug. 8. Biofuel groups have largely expressed support for the proposal but also outlined several ways to improve the rulemaking.

In celebration of World Biodiesel Day, MOL Group on Aug. 8 announced SAF was successfully produced for the first time at INA’s Rijeka Refinery during a pilot project to process biocomponent. Renewable diesel was also produced.

Upcoming Events