Novozymes launches biological foam control for sugarcane ethanol

Novozymes

November 8, 2016

BY Novozymes

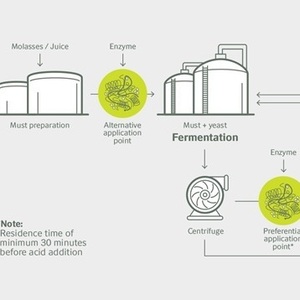

Novozymes recently launched Fermax, an enzyme protease that prevents foam development during the sugarcane ethanol fermentation process, while delivering improved control and replacing chemicals. For an average size plant, trialing partners also experienced a cost reduction of up to 20 percent when using Fermax, as compared with use of chemicals.

“This is the first ever biological solution that prevents foam development during the fermentation process, which is a critical issue for producers,” says Daniel Cardinali, Novozymes’ head of sugarcane platform and biorefining for Latin America. “With Fermax, sugarcane ethanol producers can use sustainable enzyme technology to lower their costs, reduce the need for harsh chemicals, and increase the amount of ethanol they can produce in their fermentation tanks.”

Foam develops during the fermentation process as the yeast produces ethanol and carbon dioxide. The carbon dioxide creates foam, which can cause overflow of the fermentation tank and lead to production losses. Excessive foaming also forces plants to increase fermentation time and operate at lower capacity.

100 percent dispersant reduction, 70 percent anti-foam chemicals reduction

Advertisement

Ethanol producers typically use a combination of anti-foam and dispersant chemicals to reduce the formation of foam, but their performance varies according to process and feedstock conditions.

Fermax delivers predictability and consistency. It helps stabilize the fermentation process to remove the variation seen in current, chemical-based technologies.

Unlike traditional anti-foam products, Fermax does not remove the foam, but prevents it from forming in the first place. The enzyme changes the foam structure by breaking down the stabilizing proteins to make it lighter and less dense. This enables better fermentation control, which allows producers to operate their plants more efficiently.

Fermax can completely replace, or work in combination with, traditional dispersant chemicals to boost their activity. It can also save up to 70 percent of anti-foam chemicals.

Advertisement

“This enzyme is a very cost-efficient solution, competitive with harsh chemicals, but without all their hidden costs, including supply issues, yeast damage, and incrustation,” explains Cardinali. “Sugarcane ethanol producers have traditionally not used enzymes. With Fermax, we start to apply the fascinating power of nature also within this growing industry to further improve production economics.”

Fermax is easily applicable across a variety of plant configurations, i.e. continuous/batch fermentation and continuous/batch yeast treatment.

Related Stories

Calumet Inc. on Aug. 8 confirmed its Montana Renewables biorefinery is currently running at full capacity. An initial phase of the company’s MaxSAF initiative remains on track to boost SAF capacity to up to 150 MMgy by mid-2026.

The USDA maintained its outlook for 2025-’26 soybean oil use in biofuel production in its latest World Agricultural Supply and Demand Estimates report, released Aug. 12. The forecast for soybean oil prices was also unchanged.

U.S. soybean production for 2025 is forecast at 4.29 billion bushels, down 2% when compared to last year, according to the USDA National Agricultural Statistics Service’s latest monthly Crop Production report, released Aug. 12.

Marathon Petroleum Corp. on Aug. 5 released second quarter financial results, reporting improved EBITDA for its renewable diesel segment. The company primarily attributed the improvement to increased utilization and higher margins.

Chevron Corp. on Aug. 1 confirmed the company started production at the Geismar renewable diesel plant in Louisiana during the second quarter after completing work to expand plant capacity from 7,000 to 22,000 barrels per day.

Upcoming Events