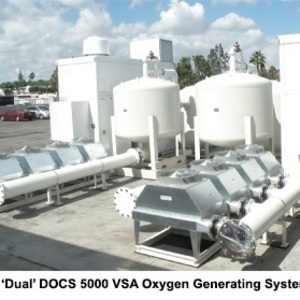

PCI Gases: DOCS can replace use of liquid oxygen in gasification

January 14, 2020

BY PCI Gases

PCI Gases, a leading global manufacturer of VSA (vacuum swing adsorption) oxygen generating systems, offer the DOCS (deployable oxygen concentrator system) as an attractive and safe on-site alternative to using liquid oxygen (LOX) or other oxygen technologies for your gasification process. Our systems range from 340 lbs. per day to 20 tons per day (oxygen flow rate).

The gasification process is accomplished using air or oxygen-enriched air as a partial oxidation agent. The required level of oxygen-enrichment is a function of the desired syngas composition. “Our systems are designed for low cost, high volume oxygen,” says Frederick B. Morgan, director of sales and business development – North America for PCI Gases. “Our unique proprietary technology leads to 50 percent less power consumption compared to competitive technologies (PSA) which results in very low operating costs along with significantly less preventive maintenance during the year. “Compared to using liquid oxygen (LOX), no more semi-annual or annual price increases/contracts. Become independent from your current oxygen supplier. Our systems are fully automatic. Easy to operate and maintain.”

VSA Technology

To produce oxygen from air, PCI uses a proprietary vacuum swing adsorption (VSA) process that eliminates many of the design problems associated with traditional on-site gas separation systems (PSA). Our innovative VSA system eliminates the need for process valves, feed air compressors, associated dryers and feed air filtering systems. Our robust VSA process extracts maximum sieve and power efficiencies = low cost (both CapX and OpX) high purity oxygen generation. Oxygen produced is 93% purity. Additional product/systems features include load following, remote monitoring and diagnostics along with an industry only 10-year warranty on the adsorber bed vessel. Average life span of our systems is 10-15+ years.

Benefits of On-Site Oxygen Generation Vs Liquid Oxygen

Why pay for cryogenic oxygen (LOX) when you can generate your own gas with a PCI On-Site Oxygen Generating System allowing you to:

- Eliminate logistic issues, i.e.: runouts, cylinder handling

- Eliminate high cost purchased gases

- Eliminate long term contracts

- Eliminate semi-annual/annual price increases

- Eliminate rental and handling charges

- Eliminate delivery & fuel sur-charges

- Eliminate evaporation losses

Bottom-Line… A PCI Gases System allows you to produce oxygen when and where you need it.

Advertisement

Advertisement

Advertisement

Advertisement

Related Stories

The U.S. Department of Energy Bioenergy Technologies Office (BETO) announced up to $23 million in funding to support research and development (R&D) of domestic chemicals and fuels from biomass and waste resources.

The U.S. DOE has announced its intent to issue funding to support high-impact research and development (R&D) projects in two priority areas: sustainable propane and renewable chemicals and algal system cultivation and preprocessing.

Sens. Sherrod Brown, D-Ohio, and Pete Ricketts, R-Neb., in August introduced the Renewable Chemicals Act, a bill that aims to create a tax credit to support the production of biobased chemicals.

The Chemical Catalysis for Bioenergy Consortium, a consortium of the U.S. DOE’s Bioenergy Technologies Office, has launched an effort that aims to gather community input on the development of new biomass processing facilities.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

Upcoming Events