Rail, truck loading skid designs aim to mitigate multiple risks

PHOTO: S&S Technical

November 12, 2015

BY Pete Singleton

Loading of rail cars and trucks seems, on the surface, to be a very simple process, but it can hide risks that can result in citations and fines or, worse, death. Having spent nearly 22 years helping a multitude of companies that load and unload trucks and rail cars, one thing holds true, project managers, engineers or EHS (environmental health and safety) professionals face a confusing landscape of guidelines, regulations and solutions offered by various suppliers. They have to consider fall protection, ergonomics, spill containment, vapor recovery, grounding and bonding, overfill prevention, emergency shutdown of systems, plus various permissives to ensure all safety protocols are in place before loading and unloading begins—all with no real standard model of what “good” looks like.

Many companies have adopted their own standard safety protocol based on what good looks like to them and with the intent of meeting regulations and guidelines. Most do a fair job. But following is an example of where the confusion can start.

We have all seen countless articles written about OSHA 1910 Subpart D, OSHA 1926, the General Duty Clause, letters of interpretation on rolling stock and the OSHA Hierarchy of Controls. Only a few aspects of loading or unloading rail cars and trucks are addressed, with the primary one being falls. Out of the gate, one of the first things to consider is how to work safely on top of a rail car or truck that can be 10 to 13 feet above the ground. Should you use active fall protection equipment like overhead trolley beams or tie off points with full body harnesses and retracting lifelines or should you consider a passive system like guardrails or cages that surround an operator and keep them from falling? This one topic in itself can lead to a lengthy discussion covering products, initial cost, long-term cost of ownership, increased productivity, lower insurance cost, personnel buy-in and adoption, various sizes, lengths and configurations of the cars and trucks, and so forth. Both active and passive fall protection are solutions supplied by many well-qualified manufacturers that meet OSHA and state regulations. Installing fall protection is a necessity when designing and building a truck or rail car loading or unloading rack and it’s best to consult with both internal and external resources to decide which direction to take, because each has it pluses and minuses.

Operator Protection

What other risks exist? And, how does one go about identifying and mitigating them? A thorough process safety analysis taken up by a team of all stakeholders from EHS, operations, logistics and engineering looking at the entire loading and unloading process will uncover those risks. At times, it’s good to consider bringing in a third-party consultant to provide an outside perspective. When doing a process safety analysis, it’s important to look at the entire process from the truck or car arrival to completion of the loading or unloading process and departure.

Consider the loading of a rail car through an open dome. Once fall protection is in place, the team must consider what the operator will use to load the car. The choices are hoses or loading arms with swivel joints. Hoses can be heavy and difficult to maneuver and can cause lifting, back-strain injuries. Initially lower cost, hoses can rupture and thus require an ongoing cost for inspection and replacement. Hoses can cause a tripping hazard if not stored properly. Heavy valves and cover plates cannot typically be left connected to the hose end, requiring the operator to carry the equipment to the top of the car. To mitigate these risks, one can utilize a hose handler, making it easier to swing the hose out to the car and minimizing the heavy lifting. Replacing hoses is easy and does not require the rack to be shut down. The hose handler allows the hose to be stored away from the loading rack walking and working areas, eliminating the trip hazards. Loading arms are made of hard pipe and swivels and have a higher initial cost.

Loading arms offer other advantages. They will not rupture or burst and, with spring balance mechanisms, are easy to move. Heavy valves and cover plates can be hung on the arm ends, further reducing the risk associated with lifting and carrying the equipment to the top of the rail car from the loading rack. Loading arms can last 20-plus years, although swivel joints do leak and require seals to be replaced. Depending on the configuration of the loading arm and type of swivel joint, the rail rack must be shut down to do arm maintenance and, in some cases, must be taken down with heavy equipment, increasing rack down time.

Each handling solution has its pluses and minuses and is riddled with confusing information that must be weighed, much like that of the active and passive fall protection systems, in order to make the best choice.

Pumping Protection

Now, let’s look at the actual pumping, overfill detection, ground verification, fire suppression and controls. Companies that design and fabricate integrated pump skid packages are an often-overlooked safety resource and are an integral part of any loading rack design. Through controls and automation, permissives and automated shut down of equipment can be designed into the skid package to help minimize or eliminate human error and mitigate risk.

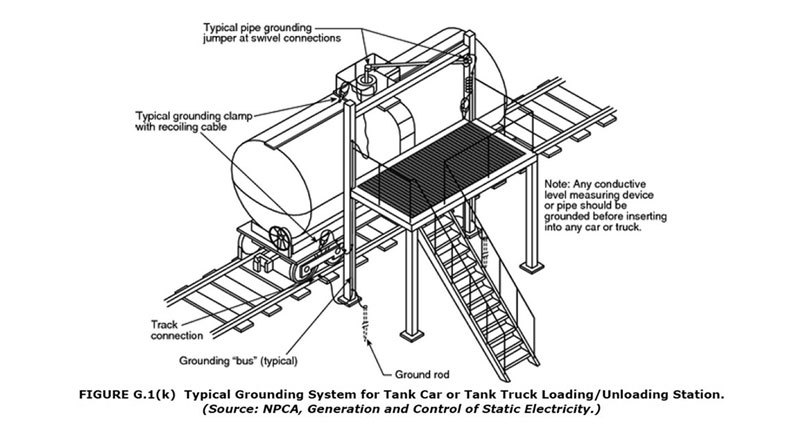

Flammable products, like ethanol, require a means to ensure the car is grounded. A ground verification unit with light indication, so an operator can visually see the car is grounded and bonded and with permissives integrated into the controls system, will ensure the pump cannot be started until a proper ground is made or shut down the pumping process should grounding be lost. The recommendations found in NFPA 77, Figure G.1(k) for typical grounding systems for tank cars or tank trucks loading/unloading stations should be considered, all of which can be monitored through automation.

Overfilling of rail cars is another risk that can be mitigated utilizing high-level systems to ensure a car is not overfilled, providing an automatic shut-off when the liquid in the car reaches a pre-determined level. Overfill can occur from inattention, by not shutting down the pump in time, or where the heel of the car was not accounted for and too much product was metered. This risk can be eliminated with well-thought-out controls and automation.

Risk of fire is very real around flammable-product loading. The instal-lation of fire suppression to knock a fire down around the rail car is known, but an overlooked area is the actual pumping skid system. To mitigate the risk, flame and gas detection sensors can be installed on and around a pumping skid system that are tied into the controls and automation package that will shut down the pump, send a signal to alert the control room, and trigger a fire suppression system on the pump skid itself. Such a system will knock a fire down independently of the rail car fire suppression equipment.

These items only cover a few of the risks found around the loading and unloading of rail cars and trucks and mitigation strategies. It’s of most importance to get a team of all stakeholders together from logistics to EHS, along with external resources, focused on the need to identify and mitigate all risks, helping eliminate confusion. Ideally, a company that can provide a complete solution is best, because it can look at the entire process. Taking the extra effort up front will help your company develop its safe loading standard and will provide a safer work environment, saving money and also making for happier employees, which, studies show, can have a direct impact on your company’s bottom line.

Author: Pete Singleton

Vice President, S&S Technical Inc.

pete@skidsolutions.com

678-867-7024

Advertisement

Advertisement

Related Stories

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The U.S. EPA on July 8 hosted virtual public hearing to gather input on the agency’s recently released proposed rule to set 2026 and 2027 RFS RVOs. Members of the biofuel industry were among those to offer testimony during the event.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

EcoCeres Inc. has signed a multi-year agreement to supply British Airways with sustainable aviation fuel (SAF). The fuel will be produced from 100% waste-based biomass feedstock, such as used cooking oil (UCO).

Upcoming Events