Renewable Diesel: A Long-Term Solution for Decarbonization

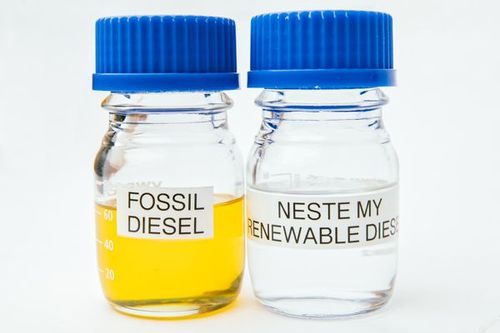

Neste MY Renewable Diesel is also known as HVO100. It is made from 100% renewable raw materials and reduces greenhouse gas emissions by up to 75% over its lifecycle, compared to fossil diesel. IMAGE: NESTE

May 22, 2025

BY Heidi Herzog

For some who don’t believe in technology neutrality and favor hydrogen or electric vehicles, renewable fuels are often described as bridge fuels, transition fuels or stopgaps. However, several major car manufacturers are scaling back on their ambitious EV production targets, which highlights the challenges and complexities of transitioning to a sustainable transportation system. There is no silver bullet to reduce all the greenhouse gas (GHG) emissions within the transportation industry, and we need to leverage all the possible solutions to fight against climate change. As a drop-in solution that works for all types of diesel engines, renewable diesel is already well positioned to be a significant player in the long-term energy landscape.

Long-Term Benefits

The biggest difference between fossil diesel and renewable diesel is the raw materials used. Fossil diesel is derived from crude oil, which accelerates climate change, while renewable diesel is produced from 100% renewable raw materials, even from waste and residue materials such as used cooking oil and animal fat waste. Hydrotreatment technology specially adapted for processing renewable materials allows carbon molecules that already exist in the environment to be used over and over again to create renewable diesel, which means that their combustion in engines does not release any new carbon into the atmosphere. The proprietary NEXBTL technology allows Neste to turn a wide variety of low-quality raw materials into premium-quality renewable products. In 2024, waste and residue materials accounted for 90% of Neste’s total renewable material inputs.

As a leading producer of renewable diesel and sustainable aviation fuel, Neste’s renewable diesel can typically deliver above 60%, even up to 75% less GHG emissions over its life cycle compared to fossil diesel. Furthermore, as a drop-in fuel, renewable diesel works in all types of diesel engines without requiring any modifications to current infrastructure. For fleet operators, the switch to renewable diesel can immediately cut the carbon footprint of their fleet without costly investment in new equipment or interruptions to business.

Neste has produced renewable diesel since 2007 and began selling it in the United States in 2012. Over the past decade, Neste has observed an increase in the consumption of renewable diesel globally as well as in the U.S., mainly driven by two factors: businesses adopting lower-GHG-emission goals and more sustainable solutions to demonstrate commitment to sustainability, as well as supportive policy frameworks like low carbon fuel standard frameworks in states like California, Oregon, Washington and New Mexico that help promote the use of renewable diesel.

Advertisement

Applications Beyond Road Transportation

Today, renewable diesel is primarily used to reduce GHG emissions from on-highway transportation. However, it is also poised to play a significant role in decarbonizing other heavy-duty segments, such as construction, mining and power generation. These harder-to-decarbonize industries rely heavily on fossil fuels for their operations and lack immediate solutions, such as electrification, to achieve net-zero emissions.

For the construction sector, renewable diesel can power heavy machinery and equipment, reducing emissions from excavation, materials handling and transportation within construction sites. Neste’s partnership with Power Engineering, a construction company specializing in heavy-civil and marine construction, is a good example. Enabled by one of Neste’s fuel distributors, Diesel Direct, Power Engineering transitioned its entire harbor craft marine fuel supply and land-based equipment fleet to run on Neste’s renewable diesel in 2023. In just one year, the switch to renewable diesel helped Power Engineering reduce up to 470 tons of GHG emissions and enabled the company to be compliant with dynamic regulations while maintaining operational performance.

For the mining industry, renewable diesel can be used in mining vehicles, blast operations, haul trucks and more to reduce its climate impact. For power generation, renewable diesel can serve as a cleaner fuel source for backup generators and remote power systems, ensuring that critical infrastructure can remain in operation during outages. In Finland and Singapore, respectively, Neste has helped data center operators Verne and ST Telemedia Global Data Centres transition to renewable diesel to power their backup generators.

Advertisement

The adoption of renewable diesel in these off-highway applications is crucial for achieving broader decarbonization goals and transitioning toward a more sustainable future. While road transportation has been a primary focus for GHG emissions reductions, renewable diesel offers a viable solution for decarbonizing these hard-to-abate sectors and complements other solutions that are in early stages of development.

Internal Combustion Engines and Liquid Biofuels

According to a recent research study commissioned by the Engine Technology Forum for heavy-duty vehicles, internal combustion engine (ICE) technology will power one-third to one-half of the new vehicle fleet in 2032. Presently, the few battery-powered and hydrogen-fueled vehicles available typically deliver shorter ranges than ICE engines. Most modern EVs offer a range of over 250 miles on a full charge, and hydrogen fuel cell vehicles can typically offer a driving range of 300 to 400 miles on a full tank of hydrogen. Multiple OEMs are developing hydrogen internal combustion engines (hydrogen ICE). According to Cummins, it has debuted two hydrogen ICE concept trucks, and the heavy-duty truck is expected to have an operating range of more than 500 miles. However, as of 2024, there are only 54 hydrogen stations in the U.S., with most of them in California. While waiting for the numbers of hydrogen vehicles and stations to grow, ICE manufacturers are continuously working to make the next generation of diesel engines combust more efficiently and reduce emissions more significantly.

While manufacturers continuously improve engines, renewable fuel producers are exploring the next generation of raw materials to produce renewable diesel. Currently, hydrotreatment is the most common process employed by commercial fuel producers, with animal fats, used cooking oil and vegetable oils being among the most common raw materials. However, these materials alone are not sufficient to meet long-term forecasted demand. To continue driving innovation, producers like Neste are working to develop technologies that can diversify supply with new, scalable materials, such as novel vegetable oils produced with regenerative farming practices and lignocellulosic waste and residue materials. Novel vegetable oils refer to renewable raw materials produced using regenerative agricultural practices that help restore soil health and increase farm productivity. For example, in early 2025, Neste signed a memorandum of understanding with Bayer that aims to develop a winter canola ecosystem in the U.S. Winter canola not only has the potential to be a lower-carbon-intensity raw material, but can also bring additional environmental benefits to cropping systems. Once they become scalable, these raw materials can play a crucial role in meeting the growing global demand for renewable products.

Renewable diesel is readily available at scale, and it can deliver immediate GHG emissions reduction for road transportation as well as a variety of heavy-duty industries. For all these reasons, it is evident that renewable diesel is not just a bridging solution, but will continue to play a vital role in the future energy mix for decades to come. We need all the available solutions to fight climate change, and renewable diesel enables us to take actions today to help transportation and heavy-duty industries operate with reduced emissions.

Author: Heidi Herzog

Commercial Director, Renewable Diesel Sales & Trading Americas

Neste

Related Stories

CARB on June 27 announced amendments to the state’s LCFS regulations will take effect beginning on July 1. The amended regulations were approved by the agency in November 2024, but implementation was delayed due to regulatory clarity issues.

Legislation introduced in the California Senate on June 23 aims to cap the price of Low Carbon Fuel Standard credits as part of a larger effort to overhaul the state’s fuel regulations and mitigate rising gas prices.

The government of Brazil on June 25 announced it will increase the mandatory blend of ethanol in gasoline from 27% to 30% and the mandatory blend of biodiesel in diesel from 14% to 15%, effective Aug. 1.

The U.S. EIA reduced its 2025 and 2026 production forecasts for a category of biofuels that includes SAF in its latest Short-Term Energy Outlook, released June 10. The forecast for 2025 renewable diesel production was also revised down.

The U.S. exported 21,545.9 metric tons of biodiesel and biodiesel blends of B30 and greater in April, according to data released by the USDA Foreign Agricultural Service on June 4. U.S. imports of biodiesel were at 4,417.3 metric tons for the month.

Upcoming Events