Researchers report a novel approach to cellulose hydrolysis

Technology journal

August 5, 2015

BY World Scientific

Cellulose hydrolysis has many industrial applications in such fields as biofuel production, food, paper, cosmetic, pharmaceutical industries and textile manufacture. A novel approach to cellulose hydrolysis using a consortium of motile bacteria moving on solid surfaces and carrying microbial luggage—another bacteria that can efficiently hydrolyze cellulose, was demonstrated by the group of Professor Eshel Ben- Jacob (R.I.P) from Tel Aviv University.

Cellulose is the most abundant polysaccharide on earth, however, it is also one of the hardest to hydrolyze. Currently, the conversion of cellulosic materials to renewable energy includes either chemical or biological hydrolysis followed by fermentation of sugars to ethanol/butanol. Utility cost of biological- enzymatic hydrolysis is low compared to chemical hydrolysis since it is usually conducted at mild conditions and does not have a corrosion problem. Biological hydrolysis is usually carried out in liquid. However, Solid State hydrolysis is financially feasible due to lower capital investment and lower operating expenses. Most cellulolytic bacteria are anaerobes with a very low growth rate and low enzyme titers.

Advertisement

Current research utilized a recombinant strain of E. coli, aerobic bacteria with high growth rate and enzyme titers. The E. coli contains ¦Â-glucosidase and cellulase genes (on pCellulose plasmid constructed in the lab of Prof. Jay Keasling). The un-motile E. coli was shown to efficiently degrade cellulose both in liquid and solid mediums.

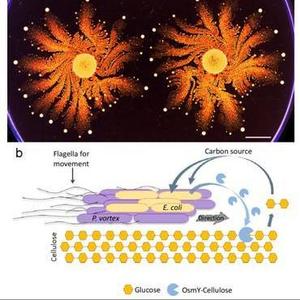

The innovation of the approach is the use of the recombinant E. coli as a microbial luggage of another highly motile bacteria- Paenibacillus vortex. Paenibacillus vortex is known for its ability to swarm (coordinated migration on solid surfaces using flagella) and collaborate with other microorganisms by carrying them in specialized structures called vortices (Fig 1 a). Thus, two bacterial species create a mutually beneficial consortium in which Paenibacillus vortexprovides a motile force while the E. coli degrades cellulose into monomers and dimers, making it available for uptake by both microorganisms.

Advertisement

Moreover, Paenibacillus vortex has the ability to degrade xylan, thus contributing its own enzymes to the consortium making it even more effective for degradation of the plant material. Since Paenibacillus vortex has the ability to swarm on solid mediums it might be relevant to use the consortium in Solid State hydrolysis of plant materials such as crops leftovers. This application of using crops needs more research, and, maybe, addition of other microorganisms relevant for fermentation. If it is be feasible it would allow easier and cheaper way to hydrolyze cellulose.

Related Stories

The U.S. Department of Energy Bioenergy Technologies Office (BETO) announced up to $23 million in funding to support research and development (R&D) of domestic chemicals and fuels from biomass and waste resources.

The U.S. DOE has announced its intent to issue funding to support high-impact research and development (R&D) projects in two priority areas: sustainable propane and renewable chemicals and algal system cultivation and preprocessing.

Sens. Sherrod Brown, D-Ohio, and Pete Ricketts, R-Neb., in August introduced the Renewable Chemicals Act, a bill that aims to create a tax credit to support the production of biobased chemicals.

The Chemical Catalysis for Bioenergy Consortium, a consortium of the U.S. DOE’s Bioenergy Technologies Office, has launched an effort that aims to gather community input on the development of new biomass processing facilities.

USDA on March 8 celebrated the second annual National Biobased Products Day, a celebration to raise public awareness of biobased products, their benefits and their contributions to the U.S. economy and rural communities.

Upcoming Events