Scientists discover a new way to convert corn waste into low-cost sugar for biofuel

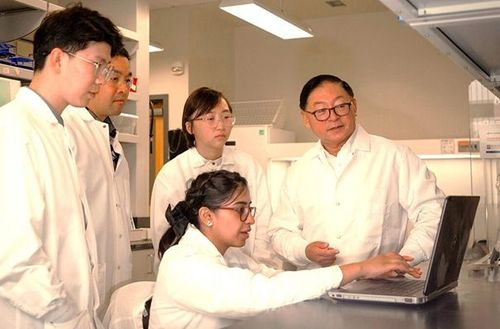

Developing new and sustainable fuels and products from biomass, Professor Bin Yang works with members of his lab at WSU Tri-Cities. Yang led research into new, economically feasible production of sugar for biofuels. / SOURCE: WSU

May 9, 2025

BY Washington State University

Scientists at Washington State University have found a new way to produce sugar from corn stalks and other crop waste, potentially opening a new pathway to sustainable biofuels.

Newly published in Bioresource Technology, their experimental process used ammonium sulfite-based alkali salts to convert corn stover — leftover corn stalks, husks, and other residues — into low-cost sugar for production of biofuels and bioproducts, making the process more economically feasible.

“Inexpensive sugar is the key to commercial success for new technologies that make fuels and useful products from renewable biomass,” said Bin Yang, professor at WSU’s Department of Biological Systems Engineering and a lead investigator on the study.

Yang and collaborators at the University of Connecticut, the National Renewable Energy Laboratory (NREL), the USDA Forest Products Lab in Madison, Wisconsin, and Washington University in St. Louis, Missouri, sought a cost-competitive way to efficiently turn cellulosic biomass — residues from corn and other tough, lignin- and cellulose-rich crops — into sugar.

Advertisement

Advertisement

Abundant and cheap, biomass holds great potential as a source of energy and valuable chemicals. But its high cost of processing, due to the difficulties in breaking down complex structural molecules like cellulose and lignin, remains a major challenge.

To unlock the vast potential benefits of this resource, it’s essential to develop new pretreatment technologies that can better break down complex polymers to produce affordable sugars.

In the paper, scientists describe how they developed a process that pretreats corn stover with potassium hydroxide and ammonium sulfite at mild temperatures. The treatment allows enzymes to break down cellulosic polymers into sugar, which can then be fermented into biofuels and bioproducts without the need for chemical recovery.

They calculated that, by offsetting the cost of production through byproduct uses or sales, the resulting sugar could be sold for as low as 28 cents per pound, making it competitive with low-cost imported sugar.

Advertisement

Advertisement

“This patent-pending process produces high-quality fermentable sugar for the biorefinery — the industrial process turning plant matter into fuel — as well as fertilizer that can replenish soil nutrients for farmers,” Yang theorized. “There’s no waste stream.”

The study appears in the July 2025 issue of Bioresource Technology as “A chemical-recovery-free ammonium sulfite-based alkali pretreatment of corn stover for low-cost sugar production via fertilizer use of waste liquor.”

The project was funded by the U.S. Department of Energy’s Bioenergy Technologies Office.

“In the next phase, we will be advancing our pretreatment technology at a pilot scale,” said Xiaowen Chen, a scientist at NREL and principal investigator on the project.

Related Stories

President Trump on July 4 signed the “One Big Beautiful Bill Act.” The legislation extends and updates the 45Z credit and revives a tax credit benefiting small biodiesel producers but repeals several other bioenergy-related tax incentives.

The USDA’s National Agricultural Statistics Service on June 30 released its annual Acreage report, estimating that 83.4 million acres of soybeans have been planted in the U.S. this year, down 4% when compared to 2024.

SAF Magazine and the Commercial Aviation Alternative Fuels Initiative announced the preliminary agenda for the North American SAF Conference and Expo, being held Sept. 22-24 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Scientists at ORNL have developed a first-ever method of detecting ribonucleic acid, or RNA, inside plant cells using a technique that results in a visible fluorescent signal. The technology could help develop hardier bioenergy and food crops.

The 2025 International Fuel Ethanol Workshop & Expo, held in Omaha, Nebraska, concluded with record-breaking participation and industry engagement, reinforcing its role as the largest and most influential gathering in the global ethanol sector.

Upcoming Events