Study shows biodiesel feedstock diversity in Germany's fuel

August 26, 2013

BY Ron Kotrba

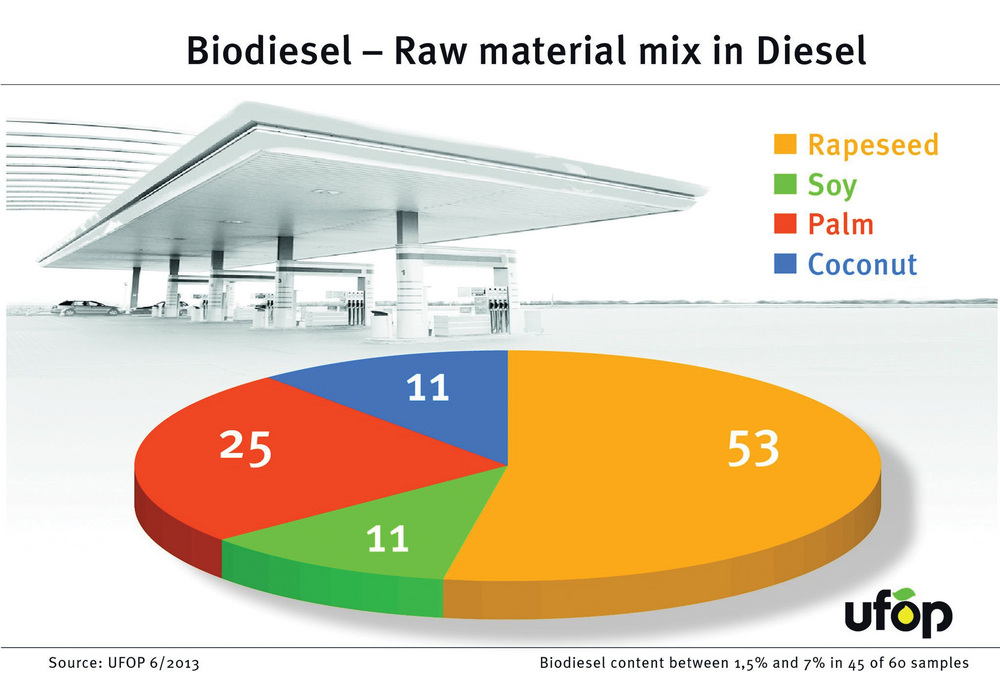

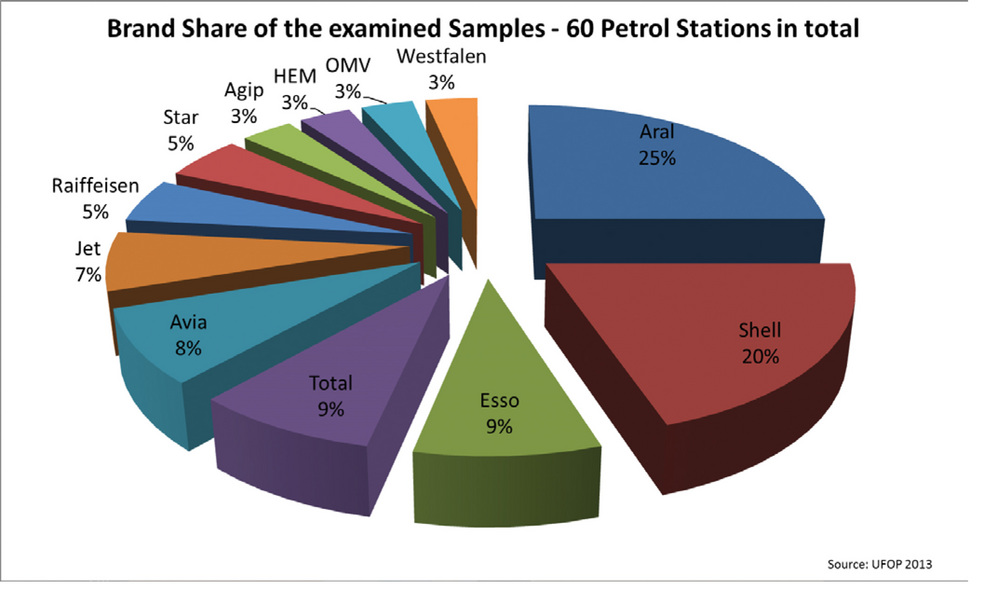

With 53 percent raw material content, rapeseed oil remains the most important raw material source for the production of biodiesel in Germany, followed by palm oil with 25 percent, and coconut and soy oil at 11 percent each. This is the result of the study presented by the Union zur Förderung von Oel- und Proteinpflanzen e.V. (UFOP). Sixty fuel filling stations throughout Germany, weighted according to market shares, were sampled. The biodiesel percentage, as well as its raw material composition, was determined on behalf of the UFOP.

In an initial analysis step, the biodiesel components of the samples were determined according to DIN EN 14078. Samples with biodiesel content greater than 1.5 percent (v/v) were then treated in accordance with DIN EN 14331. This implies a separation of the diesel matrix from the biodiesel. Finally, the fatty acid samples of the gained biodiesel fractions were determined according to DIN EN 14103. The obtained fatty acid patterns were compared with fatty acid patterns of known oils such as rapeseed, soy, palm and coconut. Ideally, an identification of the analyzed raw material basis was realized by a simulation calculation. All samples with a biodiesel content of less than 1.4 percent were designated as diesel fuels without biodiesel. This corresponds to a total number of 12 samples (out of 60 total). Of these 12 samples, 10 had a biodiesel content of less than 1 percent with five of them less than 0.5 percent.

UFOP notes that in 2010 and 2011, after the immediate national implementation of the Renewable Energies Directive, German agriculture benefitted from the fact that mostly only certified rapeseed from domestic production was available. The feedstock mix resulting from this survey reveals that the certification systems approved by the EU Commission have now also been introduced in countries outside the EU such as Argentina, Brazil as well as Indonesia and Malaysia. In other words, the supply of sustainably certified raw materials for biofuel production has become globalized since implementation of the RED, according to UFOP.

Advertisement

UFOP says it has serious misgivings and believes that closer attention must be paid to the quality of the national implementation and the certification introduced in the sense of fair competition, but also for natural and environmental protection. The RED makes it possible to examine the quality of the sustainability certification. UFOP urges the EU Commission to set out strict rules for the quality of the implementation and monitoring by the certification body as well as the responsible authorities of the member states.

Advertisement

Related Stories

BDI-BioEnergy International has signed a contract with Ghent Renewables BV to begin the construction of a pioneering biofuel feedstock refinery plant. Construction is underway and the facility is expected to be operational by the end of 2025.

Gevo subsidiary announces agreement with Minnesota Soybean Processors to track and verify sustainable agriculture attributes

Verity Holdings LLC, a subsidiary of Gevo Inc., has partnered with Minnesota Soybean Processors (MnSP) to implement Verity’s proprietary track and trace software. The collaboration aims to unlock additional value through export premiums.

A small but increasing amount of biodiesel in the United States is consumed in the residential, commercial, and electric power sectors, according to new estimates now published in the U.S. EIA’s State Energy Data System.

IAG and Microsoft are extending their 2023 co-funded purchase agreement for SAF by five years. The SAF used under the agreement will be produced by Phillips 66’s Humberside refinery and LanzaJet’s facility in the U.S.

Neste and DB Schenker, a logistics service provider, have collaborated to work towards expanding DB Schenker’s adoption of Neste MY Renewable Diesel in Asia-Pacific. DB Schenker trialed the fuel from December 2024 to February 2025 in Singapore.

Upcoming Events