The Quick and the Mobile

PHOTO: WILKS ENTERPRISE INC.

August 26, 2013

BY Ron Kotrba

Fast, portable biodiesel analyzers were never designed to certify product to ASTM D6751 specifications. They were, however, developed as convenient tools that can be used by any plant personnel, truck driver or terminal worker to gauge various fuel, or feedstock, parameters in several applications. For instance, if a blender wishes to maximize the allowable biodiesel content in diesel fuel to exploit payout from financial incentives, such as the federal $1 per gallon tax credit, state production incentives, and low carbon or RIN credit revenues, a field test can determine in seconds how much biodiesel is in the incoming fuel, and how much B100 can be added. Inside a biodiesel production facility, workers can monitor samples in-process to gauge reaction kinetics, or finished product as an ongoing quality control measure before spending precious cash on running the expensive suite of ASTM tests.

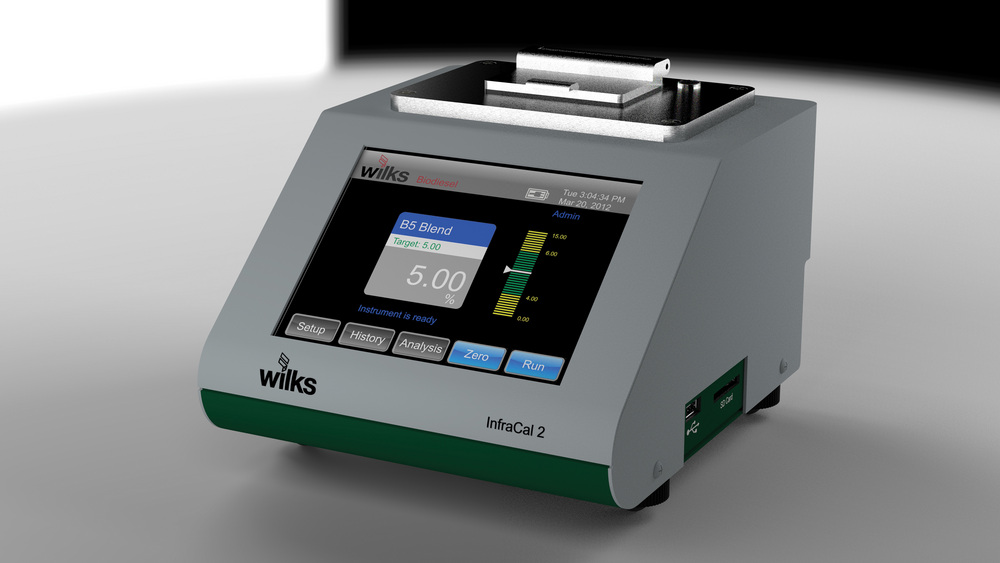

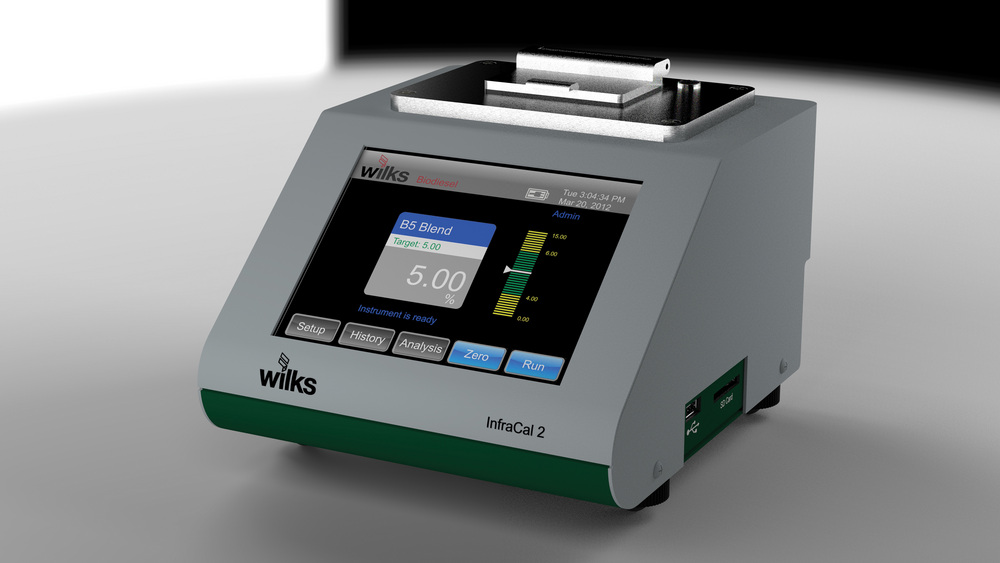

Wilks Enterprise

Wilks Enterprise Inc. has two products available in the portable biodiesel analyzer space: the InfraCal Biodiesel Blend Analyzer and the InfraSpec VFA-IR Spectrometer. The InfraCal analyzer is a fixed-filter infrared analyzer that looks at a single wavelength, the one specific for biodiesel, and determines the biodiesel percentage in a blended diesel. Results take 30 seconds and the accuracy is plus or minus 0.2 percent. The Infraspec is a spectral range analyzer that contains a linear variable filter and a detector array covering a range of wavelengths, which means it performs more than one analysis. It can be used, like the InfraCal analyzer, to determine percentage of biodiesel in a blend, but also ethanol concentration in gasoline and water content in ethanol. Wilks Enterprise President Sandra Rintoul tells Biodiesel Magazine that the InfraSpec analyzer can also measure total glycerin, but it’s not accurate enough at this test for a finished product. “We have some customers who are using it during production to gauge transesterification, but it’s not accurate enough for the finished specs—I don’t recommend it as a finished product tester,” she says. The device also detects water in biodiesel, but again it’s not sensitive enough to detect low enough levels, so if the machine detects water content in biodiesel, then there’s too much.

The company has championed development of an alternative to the ASTM D7371 method, used to determine biodiesel content in diesel fuel, which requires FTIR spectrometers. If and when passed, this would be the first portable device approved at ASTM for this, or any biodiesel, application. “The D7371 method calls for an FTIR, so because we have a filter-based spectrum analyzer, it didn’t comply,” Rintoul says, adding that a method had to be written specifically for a filter-based analyzer. “It’s actually gone through three votes—two subcommittees and it just went through a main vote last winter,” she says. “We satisfied all the negatives at this past June’s meeting, so now it’s going up again for a main committee vote Aug. 2. The voting takes 30 days, and if there’s no negatives, which, unless somebody pops out of the woodwork that hadn’t read it before, it should be amended.”

Most of Wilks’ portable biodiesel analyzers are used by customers at the terminal where blending takes place, and by state regulators. “A number of states’ weights and measures [regulators] use our equipment,” Rintoul says, including Iowa, Oregon, Washington and Minnesota. “Everyone who has a minimum state mandate pretty much has our equipment,” she says.

The units are sold calibrated or uncalibrated, and the price range for the single-wavelength analyzer is between $6,000 and $7,000. “That’s the majority of what we sell, they’re small, they’re rugged, they can go right out to the rack and survive that environment,” Rintoul says. The InfraSpec analyzer cost range is $12,000 to $13,000. Ongoing costs are minimal, and include disposable pipettes used to dispense on the sample plate, wipes and a small amount of solvent to wipe the sample plate when complete.

Advertisement

Advertisement

Koehler Instruments

Koehler Instrument Company Inc. has been in business for 85 years manufacturing petroleum instrumentation specifically for labs. It makes 164 different instruments manufactured in New York. “All of our instruments comply with the ASTM standard,” says Raj Shah, director of sales, marketing and technical services at Koehler, referring to the company’s stationary equipment. “To certify fuel as ASTM you have to run 35 to 40 tests,” he says, adding that Koehler does have a few portable biodiesel analyzers. “If I have a portable analyzer that runs flash point, for example, but it doesn’t do ASTM D93, I can say that it measures flash point with my portable analyzer for biodiesel, but I can’t use the data that I get to claim that it runs the D93. People use them to get a rough idea of what it is, and they’re a wonderful tool to get a quick answer, but you can’t really certify these portable devices unless they meet the ASTM method.”

One of the portable biodiesel analyzers Koehler offers is model number G83000, called an IS portable biodiesel analyzer. It can determine blend ranges from 2 to 100 percent biodiesel, measure total glycerin, acid number and methanol content. “Accuracy is plus or minus 1 percent and it gives results in less than 3 minutes,” Shah says. “It works on impedance spectroscopy technology. It’s a hand-held device, it’s reliable, affordable, convenient, and it can give you readings in the field, but again, I cannot certify a fuel to ASTM D6751 with it.”

Koehler’s hand-held device costs between $12,000 and $13,000, and annual operational costs are $2,000 to $3,000 for chemicals and consumables. Shah adds that Koehler is one of only a few companies in the market that also offers a device that can conveniently run D93 (flash point) procedure C. “With biofuels there’s always a little bit of water and the standard methods don’t always work if there’s water present,” he says. “That’s why they had to come up with a new method, called ASTM D93 procedure C.”

Shah commends Wilks for breaking ground in championing an ASTM method for its portable device, but he notes the limitations of this success. “It may measure a few properties, but no portable analyzer is going to be able to tell you, for example, exactly what the cloud point or oxidation stability is—portable analyzers just can’t do these kinds of tests. But they can give you a wonderful idea and are helpful tools for the manufacturing process, or quick quality control checks.”

Bonanza Labs

Advertisement

Advertisement

Bonanza Labs offers a unique, enzyme-based portable analyzer, the Mini Scan, which measures total glycerin, free fatty acid content and acid value. It’s been available for the past two-and-a-half years in the U.S., Brazil and India. “We use an enzyme that recognizes mono-, di- and triglycerides,” says Virginia Gordon, co-founder of Bonanza Labs. “The enzymes are highly specific and very sensitive.” The enzymes detect and digest mono-, di- and triglycerides, and then the byproducts of the enzymatic digestion are amplified to give a quantitative reading. “It’s a very straightforward procedure, it’s only going to measure that specific compound,” she says. “It’s not like other secondary methods that depend on interpreting spectra. It’s a primary quantitative measurement of total glycerin.”

The Mini Scan total glycerin test takes 10 minutes to run, and up to 10 samples can be run in that time frame. Gordon says the machine can also be used to test for free glycerol. “You do a water-wash and then look at the difference in toluene,” she says. “It’s quite sensitive and very repeatable. It reads down to 0.02 percent.” The quick FFA check, which can be used on incoming feedstock, takes about 30 seconds, also how long it takes to do a quick-check on the acid number.

Most Mini Scan customers are biodiesel production facilities rather than terminals or regulators. “If you have a chemist and he’s gone for three days, you can monitor and make sure everything’s running correctly in the plant,” Gordon says. “It’s a plant tool to monitor quality and processing,” she says, adding that it doesn’t take a trained lab technician to use.

Repeatability for Mini Scan total glycerin results is plus or minus 0.01 percent, according to Gordon, and correlation to gas chromatography is plus or minus 0.02 percent. With max limit for total glycerin in the 0.24 percent range, even with plants targeting 0.16 to 0.17 percent, the plus or minus 0.01 percent repeatability, and 0.02 percent correlation to GC, are “extremely good,” Gordon says.

The Mini Scan costs less than $5,000, and initial setup includes a small heating unit for the enzymes, which perform at 98.6 degrees Fahrenheit, and some small pipettes. Operational costs for the bulk test kits are about $6 a test.

Bonanza Labs has new tests in the pipeline too. “We have a test that’s in validation for glycerin purity,” Gordon says. This will allow producers to gauge the purity of their glycerin byproduct to command better pricing. The company is also working on a test to distinguish mono-, di- and triglycerides from each other. “At this point we don’t have biodiesel blend percentage analysis on the instrument,” she says, “it’s something we’re working on, but we can, however, even in a very low blend, tell you how much total glycerin is present, so you can determine in a B5 blend if the original B100 used met its original specifications.”

Author: Ron Kotrba

Editor, Biodiesel Magazine

218-745-8347

rkotrba@bbiinternational.com

Related Stories

Clean Fuels Alliance America on June 10 announced the launch of the newly redesigned BQ-9000 website, delivering a streamlined and user-friendly experience that better showcases the value of biodiesel quality assurance.

The U.S. EPA on Aug. 21 released data indicating nearly 2.04 billion RINs were generated under the RFS in August, up from 1.84 billion generated in August 2022. Total RIN generation for the first eight months of the year reached nearly 15.45 billion.

WestJet Group CEO Alexis von Hoensbroech, on Sept. 19 at the World Petroleum Congress in Calgary, addressed the airline's ambitions to achieve net-zero emissions by 2050 and the vital role SAF plays in the future of decarbonizing aviation.

Clean Fuels Alliance America, American Soybean Association, National Oilseed Processors Association the U.S. Canola Association are urging the Biden administration to adopt GREET for the purposes measuring GHG reductions for the SAF tax credit.

Montana Renewables LLC, a subsidiary of Calumet Specialty Products Partners LP, on Sept. 18 hosted an event to celebrate the first receipts of camelina oil into its biorefinery in Great Falls, Montana. The facility produces renewable diesel and SAF.

Upcoming Events