Business Briefs

PHOTO: EVONIK CORP.

January 9, 2020

BY Biodiesel Magazine

Chemical company Evonik Corp. is increasing its production capacity for biodiesel catalyst sodium methylate at its Rosario/Santa Fe facility in Argentina from 60,000 to 90,000 metric tons. The increased capacity will be built out in two stages and is expected to be complete in 2021. Evonik’s expansion of sodium methylate production is being driven by soaring biodiesel demand in Argentina and Brazil and follows several recent biodiesel production capacity additions in the region. Evonik is also investing in infrastructure and logistics improvements in South America, including expanded storage solutions in the region to ensure continuous supply reliability to its customers.

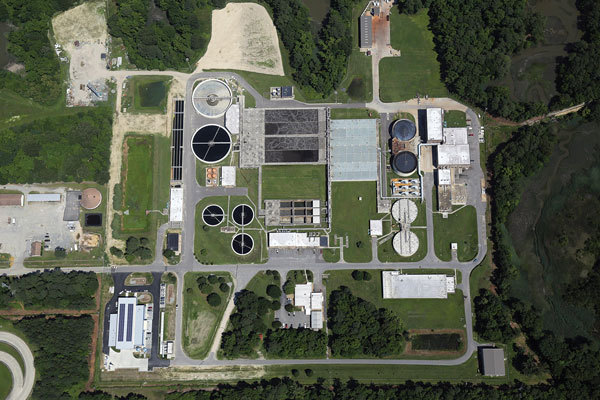

Greasezilla has been selected by Hampton Roads Sanitation District to provide fats, oils and grease (FOG) separation technology for the Nansemond Treatment Plant in Suffolk, Virginia. The construction of the new facility is expected to begin in the spring. Jacobs will be responsible for placement of the major system components and is overseeing the facility, which will screen, decant and process the FOG from indirect haulers. The Greasezilla system will sit ahead of the wastewater treatment facility and process up to 7.5 million gallons of FOG per year. Greasezilla’s two-tank, two-boiler system runs on a small fraction of the grease it separates from the wastewater. HRSD provides service to nearly 2 million people.

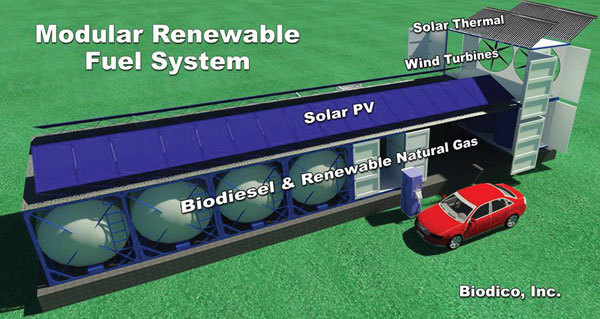

Swedish public firm Azelio AB has signed a memorandum of understanding (MOU) with U.S. biodiesel company Biodico Inc. for a project in Atascadero, California. The MOU involves Azelio’s energy storage technology beginning with commercial demonstration of Biodico’s modular biofuels system. The MOU lays out several years of collaboration between the two companies. Azelio’s technology will supply Biodico’s system with electricity on demand from wind and solar power to produce biodiesel and renewable natural gas. The California Energy Commission has pre-accepted Biodico’s commercial showcase project to apply for a full grant proposal by the end of 2019. In July, Biodico’s 10 MMgy biodiesel plant in Five Points, California, was destroyed by fire.

Oil refiner and distributor HollyFrontier Corp. plans to build a renewable diesel unit (RDU) at its Navajo refinery in Artesia, New Mexico. The RDU will have a production capacity of approximately 125 MMgy and allow HollyFrontier to process soybean oil and other feedstocks into renewable diesel. This investment will provide HollyFrontier the opportunity to meet the demand for low-carbon fuels while covering the cost of its annual RIN credit purchase obligations under the Renewable Fuel Standard. The RDU, along with corresponding rail infrastructure and storage tanks, is estimated to cost $350 million and be complete in early 2022. Construction will be funded with cash on hand and is expected to generate an internal rate of return between 20 and 30 percent.

Western Dubuque Biodiesel has received recognition from the U.S. Department of Labor’s Occupational Safety and Health Administration for achieving 1 million hours with zero lost-time accidents. The Farley, Iowa-based biodiesel production plant opened in 2006 and can produce 33 MMgy. “This award is a credit to the great team we have in Farley,” said Tom Brooks, general manager of Western Dubuque Biodiesel. “Our entire organization understands the importance of creating a safe work environment so everyone can go home to their families safe every night. We built our facility with safety foremost in our minds, and we have redundancy in our procedures to ensure it. We have buddy systems, weekly safety reviews and annual safety training, among other best-practice procedures.” Western Dubuque Biodiesel earned its BQ-9000 certification in 2007, which includes a safety component in addition to quality assurance recognition.

International biodiesel marketer and distributor Targray has opened a new biodiesel terminal in Antwerp, Belgium. Targray’s Antwerp Biodiesel Terminal is a 24/7 biofuel storage and blending center serving fuel producers, distributors, traders and retailers in markets throughout Europe. The terminal is strategically positioned within Europe’s largest petrochemical center and connects to EU customer bases through various transportation modes, including rail, sea, inland waterway, and over-the-road networks. Targray began taking orders at the new terminal in third-quarter 2019 and supplies commercial volumes of biodiesel from a broad range of feedstocks.

Advertisement

Advertisement

Related Stories

FutureFuel Corp. on March 26 announced the restart of its 59 MMgy biodiesel plant in Batesville, Arkansas. The company’s annual report, released April 4, indicates biodiesel production was down 24% last year when compared to 2023.

Neste has started producing SAF at its renewable products refinery in Rotterdam. The refinery has been modified to enable Neste to produce up to 500,000 tons of SAF per year. Neste’s global SAF production capacity is now 1.5 million tons.

Tidewater expects to make final investment decision on proposed SAF project during second half of 2025

Tidewater Renewables Ltd. has reported that its biorefinery in Prince George, British Columbia, operated at 88% capacity last year. A final investment decision on the company’s proposed SAF project is expected by year end.

BDI-BioEnergy International has signed a contract with Ghent Renewables BV to begin the construction of a pioneering biofuel feedstock refinery plant. Construction is underway and the facility is expected to be operational by the end of 2025.

Gevo subsidiary announces agreement with Minnesota Soybean Processors to track and verify sustainable agriculture attributes

Verity Holdings LLC, a subsidiary of Gevo Inc., has partnered with Minnesota Soybean Processors (MnSP) to implement Verity’s proprietary track and trace software. The collaboration aims to unlock additional value through export premiums.

Upcoming Events