Copper-based catalyst used to convert glycerin to DHA, hydrogen

Photo: Tokyo Institute of Technology

January 9, 2020

BY Tokyo Institute of Technology

Scientists at Tokyo Institute of Technology (Tokyo Tech) and the National Taiwan University of Science and Technology (Taiwan Tech) have developed a cheap and efficient copper-based catalyst that can be used to convert glycerol, one of the main byproducts of the biodiesel industry, into a valuable compound called dihydroxyacetone (DHA). In addition, this same process produces hydrogen molecules from water, and these could be used as a clean type of fuel, further highlighting the impact of this research in terms of energy sustainability.

Although governments, academia and organizations all around the world have been emphasizing the crisis concerning the use of fossil fuels for many years, their demand has constantly been on the increase. Now that supply is seriously dwindling, researchers have fervently focused on finding alternative fuels that are cleaner and with the potential for sustainable production.

Advertisement

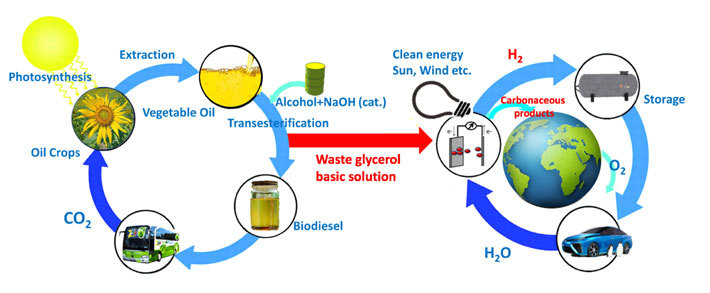

Hydrogen (H2) is a very attractive candidate as a replacement for fossil fuels because it can be produced from water (H2O) through hydrolysis, the splitting of water molecules. Another sustainable route is the synthesis of biodiesels, which are made using vegetable oils through a transformation process known as transesterification. However, biodiesel synthesis produces excessive amounts of glycerol (C3H8O3); it is estimated than the biodiesel industry in Europe alone produces a surplus of 1.4 million tons of glycerol, which cannot be sold to other industries. If glycerol could be used as a raw material to obtain more valuable chemicals, this would make the biodiesel industry more profitable, thus encouraging governments and companies to switch away from fossil fuels.

Fortunately, researchers from Tokyo Tech and Taiwan Tech recently found an efficient way to put this surplus glycerol to good use. While the electrochemical conversion of glycerol to other more valuable organic compounds, such as DHA, has been studied for years, existing approaches require the use of precious metals, namely platinum, gold and silver. Because the use of these metals represents 95 percent of the overall cost of glycerol to DHA conversion, this research team focused on finding an affordable alternative.

Advertisement

In their study, they found that copper oxide (CuO), a cheap and abundant material, could be used as a catalyst to selectively convert glycerol into DHA even at mild reaction conditions. For this to happen, the pH (concentration of free hydrogen ions) in the solution of the electrochemical cell has to be at a specific value. Through various microscopy techniques, the researchers analyzed the crystalline structure and composition of the CuO catalyst and tailored them to make it stable while also carefully inspecting the possible conversion pathways for glycerol in their system according to the solution’s pH. This allowed them to find appropriate reaction conditions that favored the production of DHA. “We have not only discovered a new, earth-abundant catalyst for high-selectivity DHA conversion, but also demonstrate the possibility of giving new valuable life to a waste product of the biodiesel industry,” said professor Tomohiro Hayashi, lead researcher from Tokyo Tech.

What’s more, the electrochemical system proposed in this study not only produced DHA from glycerol on one end, but also H2 on the other through water splitting. This means that this approach could be used to address two current problems simultaneously. “Both the biodiesel and the hydrogen generation industries could benefit from our system, leading to a more sustainable world,” Hayashi explained. A diagram of sustainable energy cycles including both the biodiesel and hydrogen industries is shown in Figure 1.

In conclusion, it is crucial that we keep trying to address the problem of sustainability in our use of fuels, and studies such as this one take us one step closer to a greener future.

Related Stories

Biodiesel capacity in the U.S. and Canada dipped slightly stable in 2024, with several renewable diesel producers reporting headwinds and lower margins alongside a drove of SAF projects in various stages of development.

The IEA’s Task 39 group has new research regarding the development and status of the sustainable aviation fuel industry.

The U.S. EPA on Nov. 16 released updated RIN data, reporting that nearly 2.11 billion RINs were generated under the RFS in October, up from 1.81 billion generated during the same month of last year.

Conestoga to host SAFFiRE cellulosic ethanol pilot plant

Conestoga Energy and SAFFiRE Renewables LLC announced on Nov. 16 their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas.

Officials at Calumet Specialty Products Partners L.P. discussed the company’s proposed plans to boost sustainable aviation fuel (SAF) production at its Montana Renewables biorefinery during third quarter earnings call, held Nov. 9.

Upcoming Events