Denmark Sets High Goals for Renewables

PHOTO: Thomas Maxe, et all, Maabjerg Energy Concept

October 5, 2012

BY Roger Moore

How does a small country, only half the size of Maine, make a technological and economic noise so big and so loud that it awakens the world from its fossil-fuel-induced fog?

If you’re Denmark, and practically surrounded by the North Sea, global warming and the anticipated rise in the ocean level tend to focus the national mind. To thrive economically, as well as survive geographically, it makes sense to concentrate the country’s scientific and engineering talents on creating green energy technology for commercial export. And, to demonstrate it on an unprecedented scale.

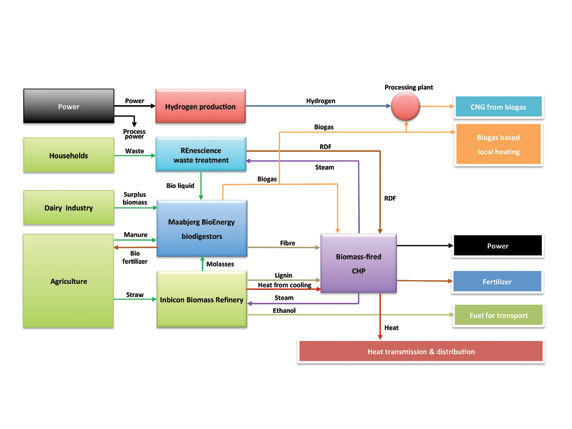

Located on a 247-acre site in northwestern Jutland, Denmark’s Maabjerg Energy Concept is, to use the technical term, huge. The project’s centerpiece is a biomass refinery using Inbicon technology that will produce 12 times more renewable energy—including 12 times more cellulosic ethanol—than Inbicon’s first refinery at Kalundborg.

The new proposed refinery is one of three large waste-to-energy plants, integrated with one another and with three smaller-scale processing technologies. They’re designed to convert an estimated 400,000 tons of wheat straw and 770,000 tons of livestock waste into a variety of clean energies and renewable products. Outputs will include about 19.3 million gallons of cellulosic ethanol, 1.7 billion cubic feet of fossil-free natural gas, green electric power for 25,000 households and heating for 20,000.

What’s more, the complex will produce 565,000 tons of renewable fertilizer for farmers and sell 56,000 tons of excess solid biofuel.

From FEED to Flow

“Because of the project’s size and scope,” says Jørgen Udby, board chair of the consortium launching the Maabjerg Energy Concept, “the first question we asked ourselves was, ‘Is it technically feasible and economically sustainable?’ And the short answer was…yes.”

Last April, following a nine-month in-depth analysis, “we presented our findings to the Climate Ministry, received approval to proceed, and entered the mobilization phase, which is more structured.”

DONG Energy, Denmark’s largest energy company, and Novozymes, the world’s largest producer of industrial enzymes, share 50 percent interest in the consortium. The participants sharing the other 50 percent are Vestforsyning and Struer Forsyning, regional public utilities from the cities of Holstebro and Struer, and the waste company Nomi. Consortium Chairman Udby also serves as Vestforsyning’s CEO.

According to Flemming Ravnholt Kanstrup, a program manager for DONG Energy, the consortium has recently hired a project director to “manage the technical side, coordinate the three main players, assess risk, make the feedstock economics work, and next spring, convince the board that the project should go ahead.”

Advertisement

COWI consulting engineers, an international firm with Danish roots, has been hired to complete the front-end engineering design (FEED) for the complete biomass refinery, based on engineering provided by Inbicon. Kanstrup says the FEED is incorporating robust upgrades based on what Inbicon learned from operating its Kalundborg demonstration plant.

By early spring of 2013, the Maabjerg Energy Concept will get the go (or no-go) decision to proceed to the next stage. If all goes well, vendor selection and detail engineering will begin then. The final investment decision will be made in early 2014, with construction to follow throughout 2015, and ethanol to flow in early 2016.

Symbiosis and Synergies

As Udby describes how the six technologies work, he also details why they perform better working together than operating alone. Often the waste stream (or byproduct) of one is recycled to become the energy or feedstock for another. These symbiotic exchanges heighten both operational efficiency and environmental performance. And they enable important synergies, such as adding a new feedstock that multiplies a particular output. Some examples include:

1. The new biomass refinery, using Inbicon technology, will produce about 30 percent of Denmark’s ethanol requirement for E10 by 2020. Two other coproducts, lignin and molasses, become feedstocks for adjacent facilities. Steam from the combined heat and power (CHP) unit cooks the straw (or most any soft lignocellulose, such as corn stalks). The heat generated could be sent to the district heating network, which becomes its cooling medium.

2. The relatively new Maabjerg BioEnergy plant, now the world’s largest biodigester, turns liquid livestock manure and butchery waste into nonfossil biogas. It will be further expanded to handle a greater quantity and variety of feedstocks, including molasses from the refinery. Adding molasses multiples the output by five times.

3. The existing biomass-fired CHP plant at Maabjerg, owned by Inbicon’s parent DONG Energy, is being modernized to continue providing the communities it serves with heat and power. After its revamp, it can burn the clean lignin produced by the biomass refinery, the residual fiber and some biogas from the biodigester, and a dry fraction from the waste treatment plant.

4. The Maabjerg municipal solid waste plant will be built to treat 50,000 metric tons of local household waste, using the REnescience enzymatic technology developed by DONG Energy’s New Bio Solutions group. It separates waste into fractions: a bioliquid used in biogas production and a dry fraction for heat and power generation.

5. The existing hydrogen generation technology could be scaled up and the hydrogen used to aid in cleaning the biogas produced by the Maabjerg BioEnergy digesters. It’s what you learned in high school chem lab—separation of water through electrolysis—but it would be powered by Denmark’s excess wind energy not needed in the electric grid.

6. A small processing unit will use the hydrogen to supplement the high-pressure water washing it does to clean the biogas. The fossil-free methane, now designated CNG, will be added to the local natural gas network for generating renewable heat and electricity.

Advertisement

All in all, the integration of the technologies is expected to not only multiply energy production but environmental protection. For example, the total CO2 reduction by the Maabjerg Energy Concept will be about 434,000 metric tons a year. According to U.S. EPA greenhouse gas calculations, that’s equivalent to taking 85,000 passenger cars off the road.

4,000 Good, Green Jobs

The location of the Maabjerg project is part serendipity. Udby, who came up with the basic idea three years ago, grew up in eastern Denmark. To take a new position, he moved west to Holstebro, later forming the company he now runs. He likes the area’s “mix of nature and culture.”

Geography also played a role. Maabjerg is on the outskirts of the city, on the way north to Struer, a smaller town on the southern lip of Denmark’s largest fjord. The land is relatively flat, the temperature moderate, the population sparse and the wheat abundant. And both the CHP station and the biogas plant were already operating.

Thomas Maxe, who manages communications for the project, stresses the employment gains. “In a slow economy, it’s all about the jobs, isn’t it?” The consortium has done a detailed study showing 4,000 new jobs will be created, many in construction, and 2,200 will be permanent. Udby has high confidence in his job numbers, plus the boost in national GDP and tax revenue expected from the $500 million investment and ongoing operation.

800,000 U.S. Jobs?

Novozymes estimates that the U.S. has the potential to create 800,000 jobs in its own cellulosic ethanol industry. That corresponds to Inbicon’s estimates as well. They, like other biomass converters, see both tough challenges and unlimited opportunities in North America.

Christian Morgen, who oversees transferring Inbicon technology to North American projects, is “very enthusiastic about the progress we’re making on similar projects in North America. We are going to the front-end-loading-2 stage, with the engineering being performed by an American firm. Although the projects are not as complex as Maabjerg, the model is very similar. And the actual biomass refineries will be about the same size. So the learning from each project is helping the other.

“And frankly, I’d like nothing better than to take advantage of our progress here in Denmark to get commercial cellulosic ethanol flowing soon from projects in North America.”

What Sets Denmark Apart

To understand how a project as ambitious as the Maabjerg Energy Complex gets the blessings of government and the cooperation of business, it’s important to recognize that Denmark is resolutely committed to making environmental protection pay off.

By 2011, as Flemming Kanstrup points out, 23 percent of Denmark’s electricity was already coming from wind, and 42 percent from the total of all renewables—wind, solar and biomass. By 2050, the Danish government is committed to producing all its energy from renewable sources.

Will Maabjerg prove to be the big bang that awakens the world to a fossil-free future? Stay tuned.

Author: Roger Moore

Communications Director, Brand Manager

Leifmark LLC

(717) 653-5700

rmoore@leifmark.com

The claims and statements made in this article belong exclusively to the author(s) and do not necessarily reflect the views of Ethanol Producer Magazine or its advertisers. All questions pertaining to this article should be directed to the author(s).

Related Stories

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

XCF Global Inc. on July 10 shared its strategic plan to invest close to $1 billion in developing a network of SAF production facilities, expanding its U.S. footprint, and advancing its international growth strategy.

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

Upcoming Events