Enerkem proposes to develop advanced biorefinery in Quebec

SOURCE: Enerkem

December 8, 2020

BY Erin Krueger

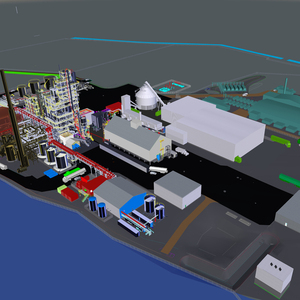

Enerkem and strategic partners Shell, Suncor, Proman and Hydro-Quebec on Dec. 8 announced plans to develop a CAD $875 biorefinery in Varennes, Quebec, that can produce 125 million liters (33.02 million gallons) of advanced biofuels, including methanol and ethanol, via a proprietary thermochemical technology.

The proposed facility, Varennes Carbon Recycling, would produce biofuels and renewable chemicals from non-recyclable residual materials and wood waste, including solid waste, mixed plastic waste and residual forest biomass. Once fully operational, the facility is expected to take in more than 200,000 metric tons of these feedstocks annually.

According to Enerkem, the proposed plant will leverage green hydrogen and oxygen produced through electrolysis. The project will include the construction of one of the world’s largest renewable hydrogen and oxygen production facilities with an 87-megawatt (MW) electrolyzer.

Advertisement

Advertisement

The project will also employ Enerkem’s proprietary thermochemical process, which produces methanol as a primary intermediary product. The renewable products produced at the facility could be used offset the use of fossil-based hydrocarbons used in transportation fuel and everyday products, such as paint, windshield washer fluid, plastics and chemicals.

The project is expected to create more than 300 jobs during construction and approximately 100 permanent jobs. Commissioning of the first phase of development is scheduled for 2023.

Advertisement

Advertisement

"We are proud to partner with leading international energy and chemical industry players and to benefit from the support of our federal and provincial governments and the City of Varennes,” said Dominique Boies, CEO and chief financial officer of Enerkem. “This strong support validates the uniqueness of our gasification technology to enable the production of circular synthesis gas. It is a major achievement for Enerkem to have its second full-scale commercial plant become a reality, showcasing our unique clean disruptive technology that transforms waste to biofuels and renewable chemicals. We have learned a great deal from our initial pilot project in Westbury, Québec and our first commercial demonstration plant in Edmonton, Alberta."

Enerkem has also developed a 38 MMly (10.04 MMgy) advanced biorefinery in Edmonton, Alberta, that utilizes its thermochemical technology.That facility, known as Enerkem Alberta biofuels, received registration approval from the U.S. EPA in 2017 to produce cellulosic ethanol under the Renewable Fuel Standard.

Related Stories

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

XCF Global Inc. on July 10 shared its strategic plan to invest close to $1 billion in developing a network of SAF production facilities, expanding its U.S. footprint, and advancing its international growth strategy.

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

Upcoming Events