ICM, IGPC Ethanol sign letter of intent

December 16, 2013

BY ICM Inc.

ICM Inc. has announced that IGPC Ethanol Inc. of Ontario, Canada, has signed a letter of intent to be the first Canadian adopter of ICM’s Generation 1.5 technology. Today’s milestone announcement will enable IGPC Ethanol to produce corn fiber cellulosic ethanol.

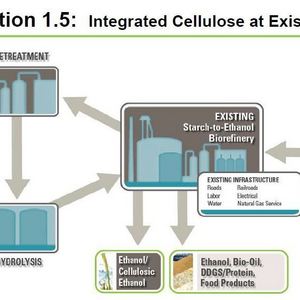

ICM has devised a line of sight for corn and other grain-based ethanol plants to create staged, platform technologies that not only enhance a plant’s efficiencies and diversify co-product opportunities, but also serve as building blocks to advance toward the next technology. Each new stage of technology advancement can be cost-justified as each one is added. ICM’s Generation 1.5 technology introduces a cellulosic ethanol production capability by adding ICM’s Fiber Separation Technologyvbuilding block onto IGPC Ethanol’s current ICM Selective Milling Technology platform. Once the FST and SMT platforms are in place, the Generation 1.5vtechnology can be added. Development of ICM’s Generation 1.5 technology was funded, in part, by a U.S. DOE Bioenergy Technologies Office contract that ICM was awarded through the American Recovery and Reinvestment Act of 2009.

ICM CEO Dave Vander Griend said, “ICM is very excited to announce that IGPC Ethanol is the first Canadian Adopter plant of our Generation 1.5 technology. We appreciate the opportunity to continue working with IGPC Ethanol to meet their goals of diversifying their ethanol plant and improve their bottom line. Today’s announcement illustrates how IGPC Ethanol is leading the industry into producing corn fiber cellulosic ethanol.”

Jim Grey, CEO of IGPC Ethanol, said, “Through our previous collaboration with ICM, we believed it was important to continue down the path of obtaining their critical platform technologies that are necessary for making a sustained impact on agriculture and economic development within our region.”

Advertisement

Advertisement

Advertisement

Advertisement

Related Stories

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

XCF Global Inc. on July 10 shared its strategic plan to invest close to $1 billion in developing a network of SAF production facilities, expanding its U.S. footprint, and advancing its international growth strategy.

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

Upcoming Events