ICP test proves yield benefits of Arisdyne cavitation technology

Arisdyne Systems Inc.

February 26, 2014

BY Arisdyne Systems Inc.

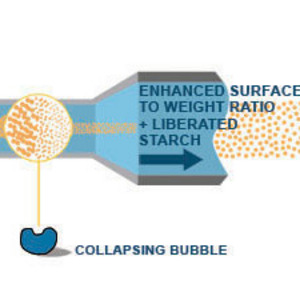

Tests of the Arisdyne Systems Inc. controlled flow cavitation process (CFC) verified that the proprietary process has increased ethanol yield by over 3 percent. The production increases were confirmed by comprehensive collaborative testing by Arisdyne and Illinois Corn Processing LLC over a 4 month testing period at their Pekin, Ill., plant. The testing at ICP helped Arisdyne reach a major milestone of 1 billion gallons of cumulative production using Arisdyne's CFC technology in ethanol production plants.

"We are delighted with the current test results and are exploring further opportunities to optimize plant operations with Arisdyne technology," said Chuck Hundt, process improvement manager at the ICP continuous fermentation plant. "Our tests validated that their equipment provided us with a reliable, cost effective way to significantly increase the yield and reduce operating costs."

Arisdyne tailored its patented control flow cavitation system for ICP, utilizing the same small footprint design used by batch processing plants. The make ready efforts for installing the system were completed well under budget in late summer with across-the-board testing through year end. "After considering alternate yield enhancement options, we concluded the Arisdyne system was more reliable, more energy efficient and had a lower overall cost," said Hundt.

"It's gratifying to work with an organization like ICP," said Fred Clarke, executive vice president of Arisdyne Systems. "We really appreciated ICP's commitment to working together with a common objective. This project has opened the doors for Arisdyne to introduce our technology and design flexibility to other continuous fermentation process producers as well as newer markets outside the dry mill industry."

Advertisement

Advertisement

Advertisement

Advertisement

Related Stories

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

XCF Global Inc. on July 10 shared its strategic plan to invest close to $1 billion in developing a network of SAF production facilities, expanding its U.S. footprint, and advancing its international growth strategy.

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

Upcoming Events