Kansas Ethanol signs agreement to use Enogen corn from Syngenta

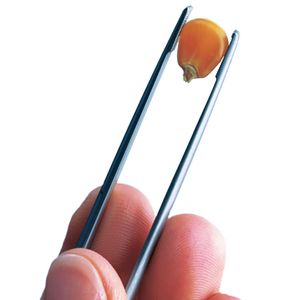

PHOTO: Syngenta

February 18, 2019

BY Syngenta

On Feb. 13, Syngenta announced a three-year marketing agreement with Kansas Ethanol LLC to use Enogen corn enzyme technology at its 80 MMgy ethanol plant in Lyons, Kansas.

Enogen corn enzyme technology is an in-seed innovation available exclusively from Syngenta and features the first biotech corn output trait designed specifically to enhance ethanol production. Using modern biotechnology to deliver best-in-class alpha amylase enzyme directly in the grain, Enogen corn eliminates the need to add liquid alpha amylase and can help an ethanol plant significantly reduce the viscosity of its corn mash, improving plant performance. Numerous trials have shown that Enogen hybrids perform equal to or better than other high-performing corn hybrids.

Advertisement

Enogen corn will provide the Kansas Ethanol facility with an industry-leading enzyme for enhanced ethanol production, while also supporting local growers and the community. The Kansas Ethanol facility will be accepting its first load of Enogen grain this fall.

“This agreement will enable us to buy more corn directly from farmers and purchase alpha amylase locally, in the form of high-quality grain,” said Mike Chisam, President and CEO of Kansas Ethanol. “We believe Enogen corn will create value for our plant, our growers and our community.”

Farmers who grow Enogen corn are eligible to earn an additional premium per Enogen bushel. To date, more than $100 million in premiums have been paid to Enogen growers. According to data from Iowa State University, these premiums create an additional $63 million in economic activity for a total of $163 million in cumulative economic benefit to the region.

Advertisement

“We are proud to partner with Kansas Ethanol to help keep enzyme dollars local and help them invest in their local community,” said Jeff Oestmann, head, biofuels operations—Enogen at Syngenta. “Syngenta is committed to the success of the ethanol industry through helping plants operate more efficiently and providing growers the opportunity to serve as enzyme suppliers.”

Related Stories

CoBank’s latest quarterly research report, released July 10, highlights current uncertainty around the implementation of three biofuel policies, RFS RVOs, small refinery exemptions (SREs) and the 45Z clean fuels production tax credit.

The USDA significantly increased its estimate for 2025-’26 soybean oil use in biofuel production in its latest World Agricultural Supply and Demand Estimates report, released July 11. The outlook for soybean production was revised down.

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

XCF Global Inc. on July 10 shared its strategic plan to invest close to $1 billion in developing a network of SAF production facilities, expanding its U.S. footprint, and advancing its international growth strategy.

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

Upcoming Events