NUS engineers pioneer new technique for biofuel production

National University of Singapore

April 16, 2018

BY National University of Singapore

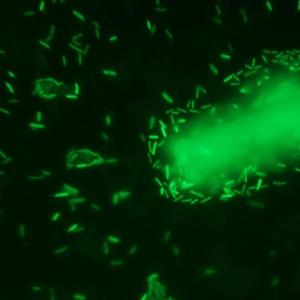

A team of engineers from the National University of Singapore recently discovered that a naturally occurring bacterium, Thermoanaerobacterium thermosaccharolyticum TG57, isolated from waste generated after harvesting mushrooms, is capable of directly converting cellulose, a plant-based material, to biobutanol.

A research team led by Associate Professor He Jianzhong from the Department of Civil and Environmental Engineering at NUS Faculty of Engineering first discovered the novel TG57 strain in 2015. They went on to culture the strain to examine its properties.

Jianzhong explained, "The production of biofuels using non-food feedstocks can improve sustainability and reduce costs greatly. In our study, we demonstrated a novel method of directly converting cellulose to biobutanol using the novel TG57 strain. This is a major breakthrough in metabolic engineering and exhibits a foundational milestone in sustainable and cost-effective production of renewable biofuels and chemicals."

Biobutanol - An attractive biofuel

Advertisement

Advertisement

Traditional biofuels are produced from food crops. This approach is highly costly and competes with food production in the use of land, water, energy and other environmental resources.

Biofuels produced from unprocessed cellulosic materials such as plant biomass, as well as agriculture, horticultural and organic waste, are expected to meet growing energy demands without increasing greenhouse gas emissions resulting from the burning of fossil fuels. These cellulosic materials are in great abundance, environmentally friendly, and economically sustainable.

Among various types of biofuels, biobutanol offers a great promise as petrol substitute because of its high energy density and superior properties. It can directly replace gasoline in car engines without any modification. However, commercial production of biobutanol has been hampered by the lack of potent microbes capable of converting cellulosic biomass into biofuels. The current technique is costly and also requires complicated chemical pre-treatment.

Producing biofuel the green way

The novel technique developed by the NUS team could potentially be a game-changing technology for cost effective and sustainable biofuel production.

Advertisement

Advertisement

Spent mushroom compost—typically composed of wheat straw and saw dust—is the residual compost waste generated by mushroom farming. The microorganisms in the waste are left to evolve naturally for more than two years to obtain the unique TG57 strain.

The fermentation process is simple, and no complicated pre-treatment or genetic modification of the microorganisms is required. When cellulose is added, the bacterium simply digests it to produce butanol as the main product.

Moving forward, the research team will continue to optimize the performance of the TG57 strain, and further engineer it to enhance biobutanol ratio and yield using molecular genetic tools.

Related Stories

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

XCF Global Inc. on July 10 shared its strategic plan to invest close to $1 billion in developing a network of SAF production facilities, expanding its U.S. footprint, and advancing its international growth strategy.

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

Upcoming Events